Contact Info

Room 503, Block D, New City Center, Wanhui Road, Xiqing District, Tianjin

PE 100-RC (RC = resistant to cracks), Modified PE 100, PE100 RC, for pipes with even higher performance, make the service life up to longer. In practice, this strengthening endows the pipes with a much greater ability to withstand the mechanical attacks to which they may be subjected during their service life, such as notching to their outer surface and resisting sharp point loads created by stones.

RC pipes are produced with PE100 with high SCG resistance checked through various tests, among which FNCT (Full Notch Creep Test) and PLT (Point Loading Test) that determine a resistance value ≥ to 100 years to severe damage, either real or under point load test conditions. The pipes are compliant with UNI EN 12201, ISO 4427, UNI EN ISO 15494.

PE100 RC (Resistant to Crack) sometimes known as Extreme Stress Crack Resistant (ESCR) or High-Stress Crack Resistant (HSCR) compounds, are defined in the German publicly available standard: PAS 1075:2009-04. PE100 RC compounds are designed to provide lifelong resistance (>100 years) to traditional Slow Crack Growth (SCG) failures caused by rock impingement and point loading stress.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

| Products details information | |

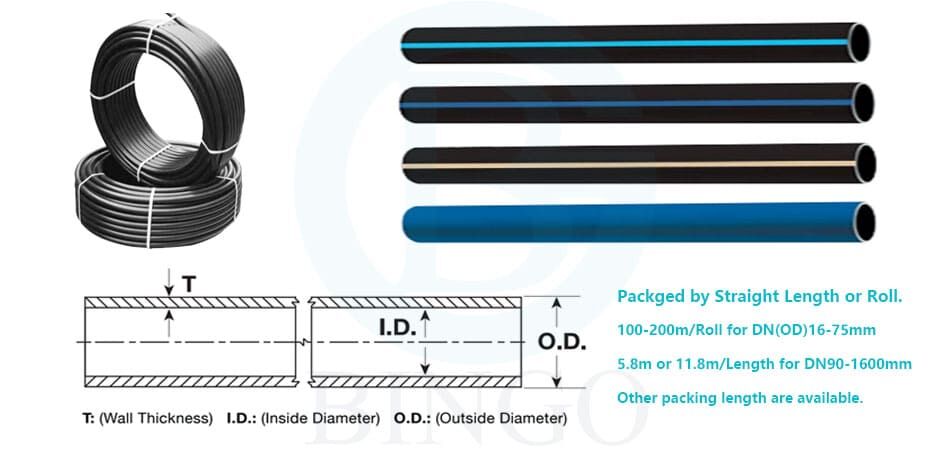

| Product name | PE100-RC HDPE Pipe for Water & Gas |

| Dia Ranges | DN20-2000mm(1/2 inch-80 inch) |

| Raw material | PE100RC... |

| Application | drinking water, fresh water, drainage, mining, dredging, marine, industry, chemical... |

| Color | Black with blue stripes, blue for water, balck with orange stripes or yellow for gas & oil |

| Standards | ISO 4427,EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, DIPS, ASTM F714 for water; ISO4437, EN1555, AS/NZS4130, ASTM D3035 etc. for gas |

| Matching products | HDPE pipe fittings, Customized PE fittigns,DI/ Steel backing ring flanges, Valves, water meter, flow gauge, welding machines and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

PE 100-RC (RC = resistant to cracks), Modified PE 100, PE100 RC, for pipes with even higher performance, make the service life up to longer. In practice, this strengthening endows the pipes with a much greater ability to withstand the mechanical attacks to which they may be subjected during their service life, such as notching to their outer surface and resisting sharp point loads created by stones.

RC pipes are produced with PE100 with high SCG resistance checked through various tests, among which FNCT (Full Notch Creep Test) and PLT (Point Loading Test) that determine a resistance value ≥ to 100 years to severe damage, either real or under point load test conditions. The pipes are compliant with UNI EN 12201, ISO 4427, UNI EN ISO 15494.

PE100 RC (Resistant to Crack) sometimes known as Extreme Stress Crack Resistant (ESCR) or High-Stress Crack Resistant (HSCR) compounds, are defined in the German publicly available standard: PAS 1075:2009-04. PE100 RC compounds are designed to provide lifelong resistance (>100 years) to traditional Slow Crack Growth (SCG) failures caused by rock impingement and point loading stress.

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Nominal Size DN (mm) |

| 50 | 1.97 | 6.9 | 5.6 | 4.6 | 3.7 | 3.0 | 2.4 | 2.0 | 1.52 | 50 |

| 63 | 2.48 | 8.6 | 7.1 | 5.8 | 4.7 | 3.8 | 3.0 | 2.5 | 1.91 | 63 |

| 75 | 2.95 | 10.3 | 8.4 | 6.8 | 5.6 | 4.5 | 3.6 | 2.9 | 2.27 | 75 |

| 90 | 3.54 | 12.3 | 10.1 | 8.2 | 6.7 | 5.4 | 4.3 | 3.5 | 2.73 | 90 |

| 110 | 4.33 | 15.1 | 12.3 | 10.0 | 8.1 | 6.6 | 5.3 | 4.2 | 3.33 | 110 |

| 125 | 4.92 | 17.1 | 14.0 | 11.4 | 9.2 | 7.4 | 6.0 | 4.8 | 3.79 | 125 |

| 140 | 5.51 | 19.2 | 15.7 | 12.7 | 10.3 | 8.3 | 6.7 | 5.4 | 4.24 | 140 |

| 160 | 6.30 | 21.9 | 17.9 | 14.6 | 11.8 | 9.5 | 7.7 | 6.2 | 4.85 | 160 |

| 180 | 7.09 | 24.6 | 20.1 | 16.4 | 13.3 | 10.7 | 8.6 | 6.9 | 5.45 | 180 |

| 200 | 7.87 | 27.4 | 22.4 | 18.2 | 14.7 | 11.9 | 9.6 | 7.7 | 6.06 | 200 |

| 225 | 8.86 | 30.8 | 25.2 | 20.5 | 16.6 | 13.4 | 10.8 | 8.6 | 6.82 | 225 |

| 250 | 9.84 | 34.2 | 27.9 | 22.7 | 18.4 | 14.8 | 11.9 | 9.6 | 7.58 | 250 |

| 280 | 11.02 | 38.3 | 31.3 | 25.4 | 20.6 | 16.6 | 13.4 | 10.7 | 8.48 | 280 |

| 315 | 12.40 | 43.1 | 35.2 | 28.6 | 23.2 | 18.7 | 15.0 | 12.1 | 9.70 | 315 |

| 355 | 13.98 | 48.5 | 39.7 | 32.2 | 26.1 | 21.1 | 16.9 | 13.6 | 10.90 | 355 |

| 400 | 15.75 | 54.7 | 44.7 | 36.3 | 29.4 | 23.7 | 19.1 | 15.3 | 12.30 | 400 |

| 450 | 17.72 | 61.5 | 50.3 | 40.9 | 33.1 | 26.7 | 21.5 | 17.2 | 13.80 | 450 |

| 500 | 19.69 | 67.6 | 55.8 | 45.4 | 36.8 | 29.7 | 23.9 | 19.1 | 15.30 | 500 |

| 560 | 22.05 | 75.7 | 62.5 | 50.8 | 41.2 | 33.2 | 26.7 | 21.4 | 17.20 | 560 |

| 630 | 24.80 | 85.1 | 70.3 | 57.2 | 46.3 | 37.4 | 30.0 | 24.1 | 19.30 | 630 |

| 710 | 27.95 | 95.9 | 79.3 | 64.5 | 52.2 | 42.1 | 33.9 | 27.2 | 21.80 | 710 |

| 800 | 31.50 | 89.3 | 72.6 | 58.8 | 47.4 | 38.1 | 30.6 | 24.50 | 800 | |

| 900 | 35.43 | 81.7 | 66.2 | 53.3 | 42.9 | 34.4 | 27.60 | 900 | ||

| 1000 | 39.37 | 90.2 | 72.5 | 59.3 | 47.7 | 38.2 | 30.60 | 1000 | ||

| 1200 | 47.24 | 88.2 | 67.9 | 57.2 | 45.9 | 36.70 | 1200 | |||

| 1400 | 55.12 | 102.9 | 82.4 | 66.7 | 53.5 | 42.90 | 1400 | |||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

1.Offshore oil & gas

2.HDPE Pipe for Water Distribution System

3.HDPE pipe of potable water supply

4.Mine Dewatering and Process Slurry

5.Civil construction for water supply

6. HDPE Pipe for Organic Chemicals

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.