Contact Info

16-513, North Fangcheng District 2, Southwest Corner of the Intersection of Miyun Road and Huanghe Road, Nankai District, Tianjin, China

HDPE dredging pipe is widely used in dredging projects, waterways, wetlands, land reclamation, dewatering of sludge, lake trout and lake restoration, flooding the river or Dredging PE Pipes wamp, and many other applications used cries.

1.Delivery: 10-30 days depending on the total quantity.

2.Packing: 11.8m/ Pcs for 40ft or 5.8m/ Pcs.

3.CO (Certificate of Origin): China, CO could be provided by free.

4.Products Inspection: Raw material, production process, delivery or third-party factory inspection.

5.MOQ: Trial Order or 1*20ft containers by mixed loading.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

|

Products Details Information |

|

|

Product Name |

High-density Polyethylene (HDPE) Dredging Pipes |

|

Brand |

DRD pipeline(Customer brand is available) |

|

Dia Ranges |

DN110-2000mm(4 inch-80 inch) |

|

Raw material |

PE100, PE80, PE4710, PE3608, PE100RC... |

|

Application |

Dredge of mud, mining projects, chemical industry, sewage engineering, HDPE pipe for Marine... |

|

Color |

Black with blue stripes, black or others colors |

|

Standards |

ISO 4427, EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, ASTM F714... |

|

Matching products |

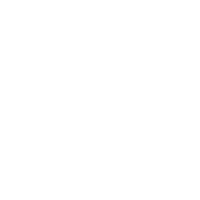

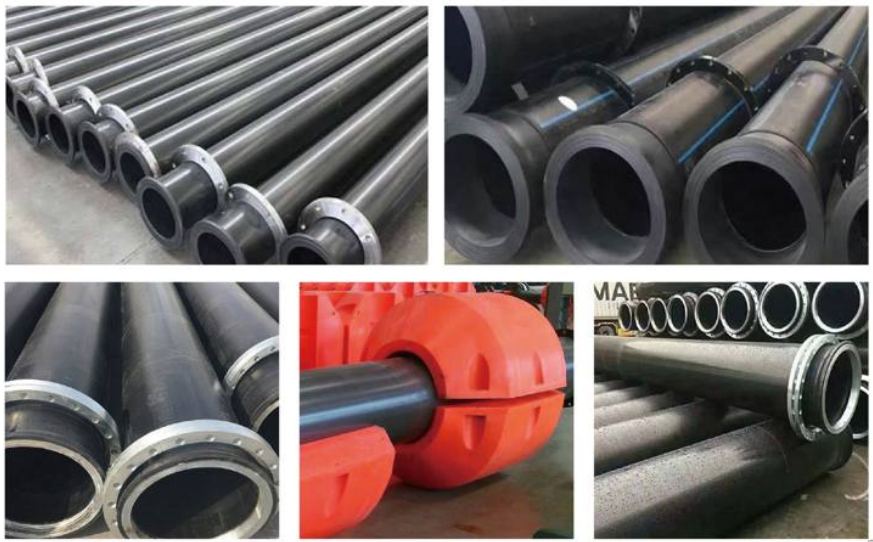

HDPE pipe fittings, customized PE fittings, floaters, rubber hose, DI/ Steel backing ring flanges, dredging mud pump, welding machines and tools, etc. |

|

Company/Factory Strength |

|

|

Production Capacity |

120*40ft containers/month |

|

Sample |

DRD free sample could be provided |

|

Quality |

QA & QC system, ensure traceability of each process |

|

Warranty |

50 years with normal use |

|

Certificates |

ISO9001, OHSAS 18001, ISO14001,CE... |

|

Delivery Time |

5-30 days, depending on the quantity |

|

Test/Inspection |

National Standard Laboratory / Pre-delivery inspection |

|

Service |

Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service |

|

Management |

Effective 8S Management System |

|

No. of Employees |

More than 300 people |

01 Light weight, saving time and improving efficiency.

HDPE dredging pipes are only one-eighth of steel pipes. They adopt flanges and bolts for connection, installation and dismantlement, which means they are convenient for transportation, repair and replacement.

02 Great flexibility, tensile strength and elasticity.

HDPE dredging pipes don't break after internal and external force impacts. It hae aront roeletanon of etormy wwovoe Thoy could ho hondod to ho a cirele hy A-9 nioooe in tha wator If thoy aro nood to he connected on land, they can be connected directly as long as the concave-convex is within 30 degrees of area.

03 Excellent wear-resistance ability.

HDPE dredging pipes wear-resistance ability is 4-8 times of steel pipe, together with its anti-UV and anti-aging ability, it normally can be used for 5-8 years upon sand content.

04 HDPE dredging pipe is assembled with two metal flanges at both pipe ends.

The pipes are connected by flanges and bolts, which ensure they will not deform and drip when installing and disassembling, ensuring the engineering's high efficiency.

05 Temperature adaptation.

HDPE dredging pipes' workable temperature range is from -40°C to 60°C. It can adapt to bad weather and fluctuating temperatures.

06 Low cost.

Whenever on land or in water, HDPE dredging pipes total engineering cost is lower and more efficient than other pipes.

HDPE dredging pipes are made by high-density polyethylene material(PE100) and are produced in various dimensions in order to use mostly on the sea to carry of sea sand for dredge of the mud. HDPE dredging pipes are manufactured and welded with the fittings as HDPE flanged pipes or HDPE two flanged pipes. The dredging pipes welded with two HDPE flange adapter and two steel flanges to be connect the pipes to each other and covered with Floaters – Floating Clamps to keep on the above sea. HDPE dredging pipes are easy to transport, installation, using of the pipes for all dredger or outfall projects. HDPE dredging pipes are preferred for agricultural applications, dredging of mud, mining projects. HDPE dredging polyethylene pipes are using together with floaters filled by Polyurethane (foam) material. Some projects need to use with Rubber hoses for the river or ocean dredging applications. For more applications, HDPE Dredgers are can be applied safely due to high resistance and longlife of the HDPE piping material.

|

Outside Diameter |

0.8MPa |

1.0MPa |

1.25MPa |

|

|

SDR21 |

SDR17 |

SDR13.6 |

||

|

75 |

2 1/2” |

3.6 |

4.5 |

5.6 |

|

90 |

3" |

4.3 |

5.4 |

6.7 |

|

110 |

4" |

5.3 |

6.6 |

8.1 |

|

125 |

5" |

6.0 |

7.4 |

9.2 |

|

140 |

5 1/2” |

6.7 |

8.3 |

10.3 |

|

160 |

6" |

7.7 |

9.5 |

11.8 |

|

180 |

6" |

8.6 |

10.7 |

13.3 |

|

200 |

8" |

9.6 |

11.9 |

14.7 |

|

225 |

8" |

10.8 |

13.4 |

16.6 |

|

250 |

10" |

11.9 |

14.8 |

18.4 |

|

280 |

10" |

13.4 |

16.6 |

20.6 |

|

315 |

12" |

15.0 |

18.7 |

23.2 |

|

355 |

14" |

16.9 |

21.1 |

26.1 |

|

400 |

16" |

19.1 |

23.7 |

29.4 |

|

450 |

18" |

21.5 |

26.7 |

33.1 |

|

500 |

20" |

23.9 |

29.7 |

36.8 |

|

560 |

22" |

26.7 |

33.2 |

41.2 |

|

630 |

24" |

30.0 |

37.4 |

46.2 |

|

710 |

28" |

33.9 |

42.1 |

52.2 |

|

800 |

32" |

38.1 |

47.4 |

58.8 |

|

900 |

36” |

42.9 |

53.3 |

66.2 |

01.Delivering powder and coal ash in thermal power plant.

02.Delivering mine tailings and slurry, metallurgical mines in the mining industry.

03.Delivering pulverized coal and coal-water slurry of coal preparation plant in the coal industry.

04.Delivering mud and corrosive media with slag in the chemical industry.

05.Delivering crude oil and petroleum.

06.Delivering sand mudslurry for dredger in dredging projects or sand suction projects, and also for seawater treatment projects.

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.