Contact Info

16-513, North Fangcheng District 2, Southwest Corner of the Intersection of Miyun Road and Huanghe Road, Nankai District, Tianjin, China

Dingrunda steel wire reinforced thermoplastic composite PE pipes (SRTP) for water supply, SRTP pipes are widely used in drinking water supply, agriculture Irrigation, civil engineering, mining, oil and gas fields ,chemical industry, power transmission pipelines, metallurgical mines, seawater transportation, shipbuilding and many other fields.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

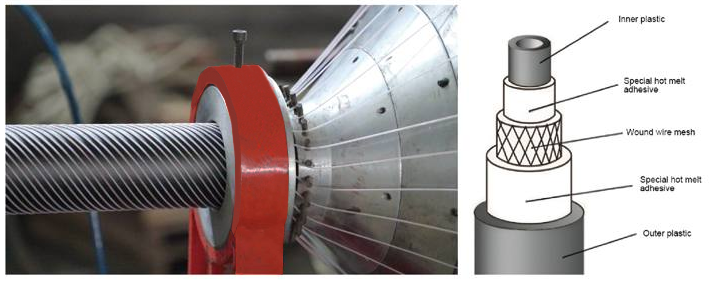

This series of products are new-type medium, high or low-pressure composite pipes reinforced by high-strength plastic-covered steel wire and covered with composite thermal plastic at internal and external surface. Owning to the reinforcement is covered in continuous thermal plastic, this kind of composite pipe not only overcomes shortcomings of steel pipes and plastic pipes, but also has common advantages of steel pipes and plastic steels.

After the galvanized pipe is prohibited, it is a revolutionary technological achievement for architectural and municipal water supply pipe and also solves the urgent needs for large-diameter rigid pipes in petroleum, chemical engineering, pharmacy, food, mine and gas field, etc. The piping system of steel wire mesh plastic reinforced composite pipes is equipped with electric melting pipe fittings. During connection, the heating elements in fittings will melt outer plastic on pipe and inner plastic on fittings and then connect them together reliably.

Properties:

01 Has the strength higher than that of plastic pipe, rigidity and impact resistance.

02 The anti-corrosive surfaces have the corrosion resistance as high as plastic pipe.

03 It is the best substitute of galvanized pipe because it is low in cost, hygienic and non-toxic.

04 Operating temperature is high and heat conductivity co-efficient is low, so insulation of outer wall is unnecessary in winter and no condensation will be formed in summer.

05 The inner wall is smooth and free of any scale sediment, so the head lossis 30% lower than that of steel pipe.

06 The technology to connect pipes by electric melting is mature, electric-melting joints are highly resistant to axial tension and multiple fittings of various specifications and varieties are available.

07 It is convenient for transportation and construction because its weight is light. This pipe is high in general reliability. And, under normal circumstances, its service life is up to 50 years.

Steel Wire Reinforced PE Pipe (SRTP)

The color is generally black and also can be decided according to mutual agreement of the supply and requisitioning parties. The internal and external surface of the pipe shall be smooth, maybe have small pits and bumps formed during natural shrinking and be free of any bubble, crack, decomposition discoloration and obvious scratch. And, two ends of the pipe shall be cut flatly.

|

Product Name |

Steel Wire Reinforced PE Pipe (SRTP) |

|

Specification |

DN20 - DN1000mm |

|

Pressure |

PN8, PN10, PN16, PN20, PN25, PN30, PN35 |

|

Raw Material |

100% Virgin Material PE100 and steel wire |

|

Standards |

ISO4437, EN1555, GB/T15558, ASTM D3035, AS/NZS4130, GOST18599, ASTM D2513,CJ/T189 |

|

Application |

Water supply, oil transportation, natural gas, mining, methane, fire fight. |

|

Connection |

Electrofusion Connection |

|

Color |

Black or Customized |

Its hygienic indexes shall meet provisions in GB/T17219 “Standard for Hygienic Safety Evaluation of Equipment and Protective Materials in Drinking Water”. The product shall meet provisions in standard CJ/T189-2007.

|

Normal Diameter (DN/OD)(mm) |

Wall thickness(mm) |

|||

|

PN8 |

PN10 |

PN16 |

PN20 |

|

|

0.8MPa |

1.0MPa |

1.6MPa |

2.0MPa |

|

|

50 |

- |

2.3 |

4.5 |

5.0 |

|

63 |

- |

2.3 |

4.5 |

5.0 |

|

75 |

- |

2.3 |

5.0 |

5.0 |

|

90 |

- |

2.3 |

5.5 |

5.5 |

|

110 |

- |

5.5 |

7.0 |

7.0 |

|

140 |

- |

5.5 |

8.0 |

8.5 |

|

160 |

- |

6.0 |

9.0 |

9.5 |

|

200 |

- |

6.0 |

9.5 |

10.5 |

|

225 |

- |

8.0 |

10.0 |

10.5 |

|

250 |

8.0 |

10.5 |

12.0 |

12.0 |

|

315 |

9.5 |

11.5 |

13.0 |

13.0 |

|

355 |

10.0 |

12.0 |

14.0 |

- |

|

400 |

10.5 |

12.5 |

15.0 |

- |

|

450 |

11.5 |

13.5 |

15.0 |

- |

|

500 |

12.5 |

15.5 |

18.0 |

- |

|

560 |

17.0 |

20.0 |

- |

- |

|

630 |

20.0 |

23.0 |

- |

- |

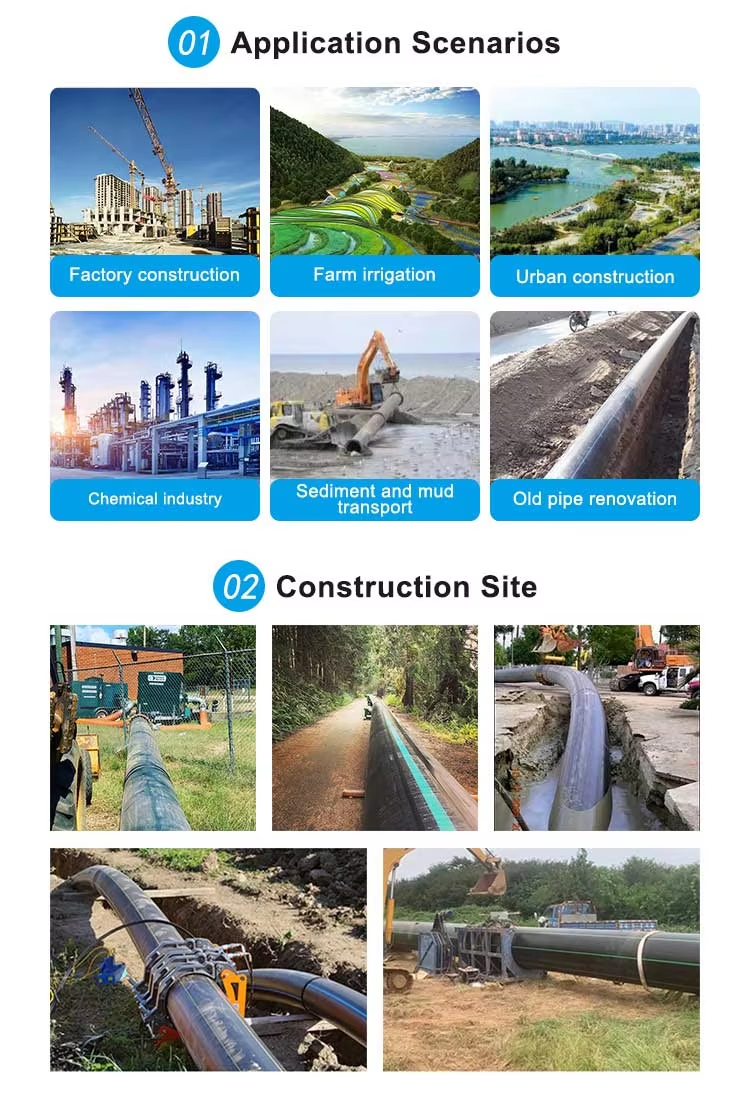

Applications:

01 Municipal engineering: urban building water supply, drinking water, fire water, heat network backwater, gas, natural gas transmission, highway buried drainage and other channels.

02 Oil field and gas field: oil sewage, gas field sewage, oil and gas mixture, second and third oil recovery and collection and transportation process pipe.

03 Chemical industry: acid, alkali, salt manufacturing industry, petroleum, chemical industry, chemical fertilizer, pharmaceutical, textile, printing and dyeing, rubber and plastic industries to transport corrosive gas, liquid, solid powder process pipe and discharge pipe.

04 Power engineering: process water, backwater, water supply, fire water, dust removal, waste slag and other pipelines.

05 Metallurgical mine: used for conveying corrosive medium and pulp, tailings, ventilation pipe and process pipe in non-ferrous metal smelting.

06 Seawater transport: seawater transport for desalination plants, seaside power plants and seaport cities.

07 Shipbuilding: ship sewage pipes, drainage pipes, ballast pipes, ventilation pipes and so on.

08 Agricultural irrigation: deep well pipe, filter pipe, culvert conveying pipe, drainage pipe, irrigation pipe etc.

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.