Contact Info

16-513, North Fangcheng District 2, Southwest Corner of the Intersection of Miyun Road and Huanghe Road, Nankai District, Tianjin, China

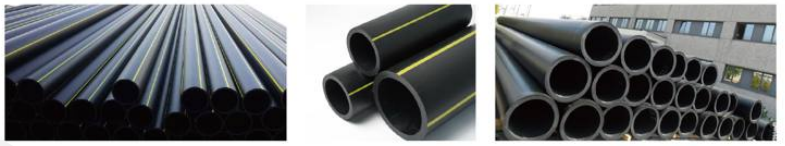

As a new type of gas transportation pipe, HDPE Gas Pipe has a wide range of main uses and applications. First of all, HDPE gas pipe is widely used in city gas transportation projects, including natural gas, liquefied petroleum gas, biogas and other gas transportation. Its excellent performance makes the gas pipe has higher safety and stability in the city gas transportation, reducing the risk of accidents.

1.Delivery: 10-30 days depending on the total quantity.

2.Packing: 11.8m or 5.8m/ Pcs for straight, 100-200m by coils for DN20-90mm.

3.CO (Certificate of Origin): China, CO could be provided by free.

4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

5.MOQ: Trial Order or 1*20ft containers by mixed loading.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

HDPE (High-Density Polyethylene) gas pipes are widely used in the transportation of natural gas and other combustible gases. These pipes are made from the thermoplastic material HDPE, which is known for its exceptional durability, flexibility, and resistance to corrosion.

|

Products Details Information |

|

|

Product Name |

High Density Polyethylene (HDPE) Natural Gas & Oil Pipes and Fittings |

|

Brand |

DRD pipeline(Customer brand is available) |

|

Dia Ranges |

DN20-630mm(1/2 inch-24 inch) |

|

Raw Material |

PE100, PE80, PE4710, PE3608, PE100RC... |

|

Application |

Oil, natural gas, methane... |

|

Color |

Black with yellow stripes, yellow or others colors |

|

Standards |

ISO4437, EN1555, GB/T15558, ASTM D3035, AS/NZS4130, GOST18599, ASTM D2513... |

|

Matching products |

HDPE pipe fittings, DI/ Steel backing ring flanges, valves, gas meters, flow gauges, welding machines and tools, etc. |

|

Company / Factory Strength |

|

|

Production Capacity |

120*40ft containers/month |

|

Sample |

Free sample could be provided |

|

Quality |

QA & QC system, ensure traceability of each process |

|

Warranty |

50 years with normal use |

|

Certificates |

ISO9001, OHSAS 18001, ISO14001,CE... |

|

Delivery Time |

5-30 days, depending on the quantity |

|

Test/Inspection |

National Standard Laboratory/ Pre-delivery inspection |

|

Service |

Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service |

|

Management |

Effective 8S Management System |

|

No. of employees |

More than 300 people |

1. Raw material introduction:

HDPE is a type of plastic made from petroleum. It is a strong, lightweight, and flexible material with high impact resistance. The raw material is mixed with various additives and then melted and extruded to form the gas pipes.

2. Performances:

HDPE gas pipes offer numerous advantages due to their material properties. Some key performances include:

- Corrosion resistant: HDPE pipes have excellent resistance to corrosion caused by chemicals, soil, and other environmental factors.

- Flexible and lightweight: HDPE pipes are highly flexible, allowing for easy installation in various terrains. Their light weight nature reduces transportation and installation costs.

- High impact strength: HDPE pipes can withstand high impact forces and provide excellent resistance against cracks and fractures.

- Longevity: HDPE gas pipes have a long service life of more than 50 years, significantly reducing maintenance and replacement costs.

- Leak-free joints: HDPE pipes have fusion-welded joints, eliminating the risk of leakage.

3. Advantages:

HDPE gas pipes have several advantages over traditional metal pipes, including:

- Cost-effective: HDPE pipes offer cost savings during installation, transportation, and maintenance, making them a cost-effective solution.

- Improved safety: The pipes are resistant to damage from external factors like earthquakes or ground movement, enhancing the overall safety of gas distribution systems.

- Environmentally friendly: HDPE pipes are recyclable, reducing their ecological impact. They can also be manufactured from recycled HDPE material.

- Enhanced flow characteristics: HDPE pipes have a smooth inner surface that promotes efficient gas flow, reducing pressure drops.

|

20mm-630mm |

SDR17.6 |

SDR11 |

SDR9 |

|

20 |

2.3 |

3.0 |

3.0 |

|

25 |

2.3 |

3.0 |

3.0 |

|

32 |

2.3 |

3.0 |

3.6 |

|

40 |

2.3 |

3.7 |

4.5 |

|

50 |

2.9 |

4.6 |

5.6 |

|

63 |

3.6 |

5.8 |

7.1 |

|

75 |

4.3 |

6.8 |

8.4 |

|

90 |

5.2 |

8.2 |

10.1 |

|

110 |

6.3 |

10.0 |

12.3 |

|

125 |

7.1 |

11.4 |

14.0 |

|

140 |

8.0 |

12.7 |

15.7 |

|

160 |

9.1 |

14.6 |

17.9 |

|

180 |

10.3 |

16.4 |

20.1 |

|

200 |

11.4 |

18.2 |

22.4 |

|

225 |

12.8 |

20.5 |

25.2 |

|

250 |

14.2 |

22.7 |

27.9 |

|

280 |

15.9 |

25.4 |

31.3 |

|

315 |

17.9 |

28.6 |

35.2 |

|

140 |

20.2 |

32.3 |

39.7 |

|

160 |

22.8 |

36.4 |

44.7 |

|

180 |

25.6 |

40.9 |

50.3 |

|

200 |

28.4 |

45.5 |

55.8 |

|

225 |

31.9 |

50.9 |

62.5 |

|

250 |

35.8 |

57.3 |

70.3 |

Oil transfer

Water transfer

Process water

Methane Gas collection

oil and gas gathering

gas distribution system

Mining

Sour and wet gas lines

Offshore oil & gas

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.