Contact Info

16-513, North Fangcheng District 2, Southwest Corner of the Intersection of Miyun Road and Huanghe Road, Nankai District, Tianjin, China

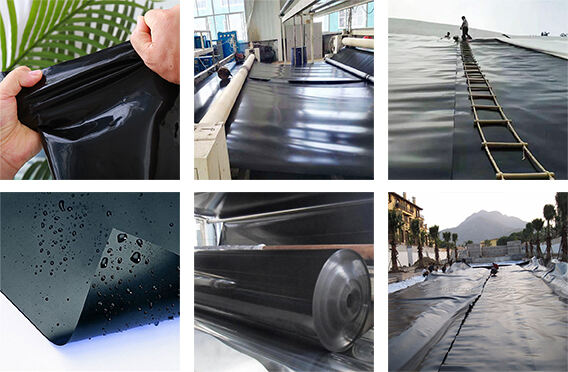

Dingrunda's Geomembranes are engineered to provide a reliable and durable barrier for a variety of containment and lining applications. These high-performance membranes are made from select polymers, offering excellent resistance to chemicals, punctures, and environmental stressors. With a smooth surface and superior flexibility, our geomembranes are designed to conform to complex shapes and contours, ensuring a tight seal and effective barrier against liquids and gases.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

Dingrunda's Geomembranes are engineered to provide a reliable and durable barrier for a variety of containment and lining applications. These high-performance membranes are made from select polymers, offering excellent resistance to chemicals, punctures, and environmental stressors. With a smooth surface and superior flexibility, our geomembranes are designed to conform to complex shapes and contours, ensuring a tight seal and effective barrier against liquids and gases.

Features:

1) Good physical and mechanic performance

2) High tearing resistance, strong deformation adaptability

3) Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance

4) Good adaptability to high and low temperature, non-toxicity, long service life

5) Good waterproof, drainage, anti-seepage and damp proof effects

6) Complete width and thickness specifications, low cost and easy installation.

Benefits:

* The most chemically resistant member of the polyethylene family due to its dense configuration.

* Field welded with hot wedge welders and extrusion welders. These factory quality welds are virtually stronger than the sheet itself.

* The best QC-QA testing capabilities in the marketplace.

* No need to cover the liner because it is UV stable and cost-effective.

* Available in roll stock and come in varying thicknesses ranging from 20 to120 mil depending on your requirements.

Chemical Resistance: Formulated to withstand exposure to a broad range of chemicals, ensuring long-term stability and performance.

Puncture Resistance: Engineered with high tensile strength to resist punctures and tears, even under heavy loads or rough handling.

Environmental Durability: Resilient against UV rays, extreme temperatures, and weathering, making them suitable for outdoor and long-term use.

Seamless Integration: Capable of being heat-welded or chemically bonded to create a watertight seal, minimizing the risk of leaks or breaches.

Versatile Application: Suitable for both temporary and permanent installations, accommodating a wide array of application-specific needs.

|

Properties |

GM0.5 |

GM0.75 |

GM1.0 |

GM1.25 |

GM1.5 |

GM2.0 |

GM2.5 |

|

Thickness |

0.50mm |

0.75mm |

1.00mm |

1.25mm |

1.50mm |

2.00mm |

2.50mm |

|

Density ( ≥) |

0.940g/cc |

0.940g/cc |

0.940g/cc |

0.940g/cc |

0.940g/cc |

0.940g/cc |

0.940g/cc |

|

Tensile Properties ( ≥) •yield strength •break strength •yield elongation • break elongation |

7 kN/m 10kN/m — 600% |

10 kN/m 15kN/m — 600% |

13 kN/m 20 kN/m 11% 600% |

16 kN/m 25 kN/m 11% 600% |

20 kN/m 30 kN/m 11% 600% |

26 kN/m 40 kN/m 11% 600% |

33kN/m 50kN/m 11% 600% |

|

Tear Resistance ( ≥) |

56 N |

84 N |

115 N |

140 N |

170 N |

225 N |

280 N |

|

Puncture Resistance ( ≥) |

120 N |

180 N |

240 N |

300 N |

360 N |

480 N |

600 N |

|

Carbon Black Content ( ≥) |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

2.0-3.0% |

|

Carbon Black Dispersion ( ≥) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

Note(1) |

|

Oxidative Induction Time(OIT) Standard OIT ( ≥) |

60 min. |

60 min. |

60 min. |

60 min. |

60 min. |

60 min. |

60 min. |

Landfill Liners: Used in landfill construction to prevent the leaching of hazardous substances into the ground.

Water Reservoirs: Ideal for lining ponds, reservoirs, and lakes to conserve water and prevent seepage.

Mining Waste Containment: Employed in the mining industry to contain tailings and prevent environmental contamination.

Agricultural Applications: Used in irrigation systems and for covering silage to protect crops and feed from spoilage.

Civil Engineering: Applied in road construction, tunneling, and other civil engineering projects to provide a protective barrier.

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.