Contact Info

Room 503, Block D, New City Center, Wanhui Road, Xiqing District, Tianjin

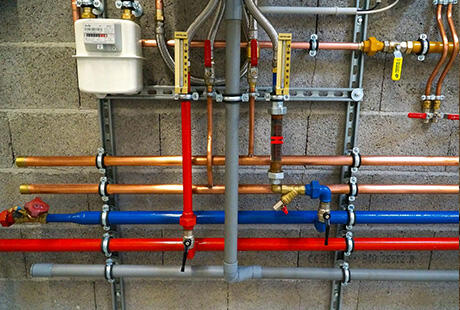

1. PVC Pipe Range: U PVC, C PVC, M PVC(PVC-UH), O PVC Pipe& Fittings

2. PVC Pipe& Fittings Standard: ISO, ASTM, GB/T, NZ/AS, Gost…

3. Application: Water, Sewer, Cable, Industrial, Drainage…

4. Pressure: PN4-PN20, SCH40/SCH80…

5. Diameter: OD20-800mm/ 1/2-32 Inch…

6. Delivery: 10-30 days depending on the total quantity.

7. Packing: 3/6/9/12m/ Pcs for straight, with plain ends, RRJ end or SCJ end.

8. CO (Certificate of Origin): China, CO could be provided by free.

9. Products Inspection: Raw material, production process, delivery or third-party factory inspection

10. MOQ: Trial Order or 1*20ft containers by mixed loading.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

| Products details information | |

| Product name | U PVC/C PVC/ M PVC Pipes and Fittings |

| Brand | Dingrunda |

| Dia Ranges | DN20-800mm(1/2 inch-32 inch) |

| Pressure Class | PN4-PN25, SCH40/SCH80 |

| Pipe Range | U PVC, C PVC, M PVC(PVC-UH), O PVC... |

| Application | PVC Pipes& fittings for drinking water, fresh water, portable water, industrial, cable, sewer, drainage... |

| Color | Grey, Blue, others colors is option |

| Standards | EN 1401, EN ISO 1452, EN ISO 15493, EN 1767, ISO4422, ASTM D1785, BS 3505, ASTM F441... |

| Matching products | PVC fittings, Solvent Cement fittings, Rubber Ring Joints, Flanges, Glue and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

1. U PVC Pipe& Fittings ASTM Schedule Series SCH40 and SCH80

2. CPVC Pipe& Fittings ASTM Schedule Series SCH40 and SCH80

3. BS 3505- 3506 Specification for unplasticized polyvinyl chloride pressure pipe

4. EN ISO 1452-2 Plastics piping systems for water supply

5. Chlorinated Polyvinyl Chloride(C-PVC) pipes system for hot and cold water

6. Modified Polyvinyl Chloride (PVC-M) pipes

7. Oriented polyvinyl chloride(PVC-O) pipes

8. UPVC Pipes and Fittings for Industrys

9. UPVC Conduits for Underground Telecommunication Cable

10. Perforated(Slotted) U PVC/PVC M pipes

1.Solvent Cement socket joints

2.Rubber ring joints

3.Flanges connection

4.Thread fittings connection

5.Union connection

6.Compression fittings connection

|

|

|

|

| Plain End | Rubber Ring End | Bell End |

Threaded End |

1. The PVC pipe is light and easy for transportation, loading, and installation with labor saving.

2. Acid, alkali, and corrosion resistance for chemical industry.

3. Smooth surface with smaller roughness coefficient of 0.009 to reduce the fluidity resistance. More flow than other material pipes in the same size.

4. Strong resistance to water pressure and outside impact, which can be applied to any piping engineering.

5. The dissolution test proves that PVC pipe is unaffected to water quality, which is the best material for running water piping.

6. Leak proof joints

7. All weather UV resistance, Protect from the effect of UV rays

8. Absolute economy in material cost, transportation & installation

| Nominal outside diameters (DN) and nominal wall thickness en based on an overall service (design) coefficient of C = 2.5 | ||||||||

| Nominal Outside Diameter DN (mm) | Pipe Series S , SDR Series and Nominal Pressure PN Equivalents | |||||||

| S 20 | S 16.7 | S 16 | S 12.5 | S 10 | S 8 | S 6.3 | S 4 | |

| SDR 41 | SDR 34.4 | SDR 33 | SDR 26 | SDR 21 | SDR 17 | SDR 13.6 | SDR 9 | |

| PN 5 | PN 6 | PN 6.3 | PN 8 | PN 10 | PN 12.5 | PN 16 | PN 25 | |

| Nominal Wall Thickness en | ||||||||

| 10 | - | - | - | - | - | - | - | 1.5 |

| 12 | - | - | - | - | - | - | - | 1.5 |

| 16 | - | - | - | - | - | - | 1.5 | 1.8 |

| 20 | - | - | - | - | - | - | 1.5 | 2.3 |

| 25 | - | - | - | - | - | 1.5 | 1.9 | 2.8 |

| 32 | - | - | - | - | 1.6 | 1.9 | 2.4 | 3.6 |

| 40 | - | - | 1.5 | 1.6 | 1.9 | 2.4 | 3.0 | 4.5 |

| 50 | - | - | 1.6 | 2.0 | 2.4 | 3.0 | 3.7 | 5.6 |

| 63 | 1.6 | 1.9 | 2.0 | 2.5 | 3.0 | 3.8 | 4.7 | 7.1 |

| 75 | 1.9 | 2.2 | 2.3 | 2.9 | 3.6 | 4.5 | 5.6 | 8.4 |

| 90 | 2.2 | 2.7 | 2.8 | 3.5 | 4.3 | 5.4 | 6.7 | 10.1 |

| Nominal outside diameters (DN) and nominal wall thickness en based on an overall service ( design) coefficient of C = 2.0 | ||||||||

| Nominal Outside Diameter | Pipe Series S , SDR Series and Nominal Pressure PN Equivalents | |||||||

| S 20 | S 16 | S 12.5 | S 10 | S 8 | S 6.3 | S 5 | ||

| SDR 41 | SDR 33 | SDR 21 | SDR 21 | SDR 17 | SDR 13.6 | SDR 11 | ||

| DN | PN 6.3 | PN 8 | PN 10 | PN 12.5 | PN 16 | PN 20 | PN 25 | |

| mm | Nominal Wall Thickness en | |||||||

| 110 | 2.7 | 3.4 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 | |

| 125 | 3.1 | 3.9 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 | |

| 140 | 3.5 | 4.3 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | |

| 160 | 4.0 | 4.9 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | |

| 180 | 4.4 | 5.5 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | |

| 200 | 4.9 | 6.2 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | |

| 225 | 5.5 | 6.9 | 8.6 | 10.8 | 13.4 | 16.6 | - | |

| 250 | 6.2 | 7.7 | 9.6 | 11.9 | 14.8 | 18.4 | - | |

| 280 | 6.9 | 8.6 | 10.7 | 13.4 | 16.6 | 20.6 | - | |

| 315 | 7.7 | 9.7 | 12.1 | 15.0 | 18.7 | 23.2 | - | |

| 355 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | - | |

| 400 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | - | |

| 450 | 11.0 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | - | |

| 500 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | - | |

| 560 | 13.7 | 17.2 | 21.4 | 26.7 | - | - | - | |

| 630 | 15.4 | 19.3 | 24.1 | 30.0 | - | - | - | |

| 710 | 17.4 | 21.8 | 27.2 | - | - | - | - | |

| 800 | 19.6 | 24.5 | 30.6 | - | - | - | - | |

| 900 | 22.0 | 27.6 | - | - | - | - | - | |

| 1000 | 24.5 | 30.6 | - | - | - | - | - | |

Notes:

|

| ASTM D1785 - Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80* | |||||||||||||

| Dimension In Inch | |||||||||||||

| Nominal Size | Outside Diameter (Inch) | SCH 40 | SCH 80 | ||||||||||

| Wall Thickness (in) | Internal Diameter | Pressure Rating | Wall Thickness (in) | Internal Diameter | Pressure Rating | ||||||||

| inch | Min (in) | Max (mm) | Max (in) | Min (in) | Max (in) | Weight (kg/m) | ID (in) | (PSI) | Min (in) | Max (in) | Weight (kg/m) | ID (in) | (PSI) |

| 1/2 | 0.840 | 0.004 | 0.844 | 0.109 | 0.226 | 0.246 | 0.622 | 600 | 0.147 | 0.167 | 0.314 | 0.546 | 850 |

| 3/4 | 1.050 | 0.004 | 1.054 | 0.113 | 0.233 | 0.326 | 0.824 | 480 | 0.154 | 0.174 | 0.425 | 0.742 | 690 |

| 1 | 1.315 | 0.005 | 1.320 | 0.133 | 0.268 | 0.484 | 1.049 | 450 | 0.179 | 0.200 | 0.627 | 0.957 | 630 |

| 1 1/4 | 1.660 | 0.005 | 1.665 | 0.140 | 0.281 | 0.656 | 1.380 | 370 | 0.191 | 0.214 | 0.864 | 1.278 | 520 |

| 1 1/2 | 1.900 | 0.006 | 1.906 | 0.145 | 0.289 | 0.783 | 1.610 | 330 | 0.200 | 0.224 | 1.047 | 1.500 | 470 |

| 2 | 2.375 | 0.006 | 2.381 | 0.154 | 0.305 | 1.053 | 2.067 | 280 | 0.218 | 0.244 | 1.448 | 1.939 | 400 |

| 2 1/2 | 2.875 | 0.007 | 2.882 | 0.203 | 0.398 | 1.671 | 2.469 | 300 | 0.276 | 0.309 | 2.209 | 2.323 | 420 |

| 3 | 3.500 | 0.008 | 3.508 | 0.216 | 0.424 | 2.186 | 3.068 | 260 | 0.300 | 0.336 | 2.956 | 2.900 | 370 |

| 4 | 4.500 | 0.009 | 4.509 | 0.237 | 0.464 | 3.111 | 4.026 | 220 | 0.337 | 0.377 | 4.320 | 3.826 | 320 |

| 5 | 5.563 | 0.010 | 5.573 | 0.258 | 0.289 | 4.213 | 5.047 | 190 | 0.375 | 0.420 | 5.988 | 4.813 | 290 |

| 6 | 6.625 | 0.011 | 6.636 | 0.280 | 0.550 | 5.469 | 6.065 | 180 | 0.423 | 0.484 | 8.236 | 5.779 | 280 |

| 8 | 8.625 | 0.015 | 8.640 | 0.322 | 0.632 | 8.234 | 7.981 | 160 | 0.500 | 0.560 | 12.510 | 7.625 | 250 |

| 10 | 10.750 | 0.015 | 10.765 | 0.365 | 0.717 | 11.671 | 10.020 | 140 | 0.593 | 0.664 | 18.544 | 9.564 | 230 |

| 12 | 12.750 | 0.015 | 12.765 | 0.406 | 0.797 | 15.429 | 11.938 | 130 | 0.687 | 0.769 | 25.519 | 11.376 | 230 |

| 14 | 14 | 0.015 | 14.015 | 0.437 | 0.859 | 18.251 | 13.126 | 130 | 0.750 | 0.840 | 30.600 | 12.500 | 220 |

| 16 | 16 | 0.019 | 16.019 | 0.500 | 0.981 | 23.864 | 15.000 | 130 | 0.843 | 0.944 | 39.340 | 14.314 | 220 |

| 18 | 18 | 0.019 | 18.019 | 0.562 | 1.101 | 31.393 | 16.876 | 130 | 0.937 | 1.049 | 51.276 | 14.126 | 220 |

| 20 | 20 | 0.023 | 20.023 | 0.593 | 1.163 | 35.432 | 18.814 | 120 | 1.031 | 1.155 | 60.226 | 17.938 | 220 |

| 24 | 24 | 0.031 | 24.031 | 0.687 | 1.347 | 49.317 | 22.626 | 120 | 1.218 | 1.364 | 85.451 | 21.564 | 210 |

| Pressure rating based on water at 23℃ for unthreaded pipes. | |||||||||||||

UPVC pipes and fittings are used in a wide range of applications including Cold Water Distribution system for bathrooms, kitchens, gardens, washing places, toilets in residential blocks, commercial complex, offices, factories, laboratories, bus stands, railways, airports, hotels and hospitals.

1. Drinking water engineering

2. Construction engineering

3. Sewer engineering

4. Well drilling engineering

5. Salt water engineering

6. Chemical factory

7. Paper mill

8. Acidifying & Fermenting plant

9. Electroplating factory

10. Agricultural Ground

11. Mining Plant

12. Aquaculture

13. Free way engineering

14. Golf course engineering

15. Fishery use for Plastic raft

|

|

| U PVC Pipes for Water Supply Applciation | U PVC Pipes for Water-Supply Systems |

|

|

| U PVC Pipes for Indoor Drainage | U PVC Pipes for Indoor Water Supply System |

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.