Contact Info

Room 503, Block D, New City Center, Wanhui Road, Xiqing District, Tianjin

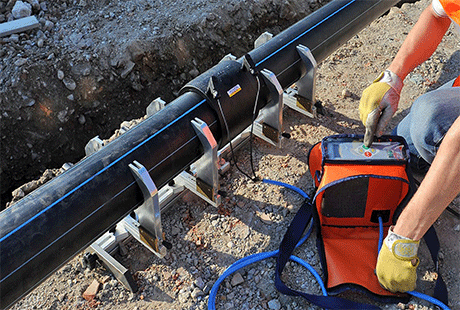

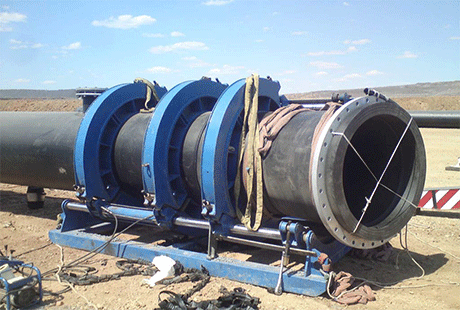

HDPE pipe and fittings welding machines provided by us are extensively used in different HDPE pipeline construction projects.

1.Welding Control: Semi-Automatic Hydraulic Type

2.Welding Range: 63-250mm

3.Application: HDPE/PP/PVDF Pipe and fittings

4.Packing: Plywood Cases

5.Warranty: 1 Year

6.MOQ: 1 Set is available

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

63-160mm Hydraulic Butt Fusion Welding Machine is applicable to connected to PE, PP, PVDF pipe and tube, pipe and pipe fittings at work site, also can be used in the workshop as well. All model machines can comply with the relevant ISO and DVS and Chinese welding standards.

|

|

|

|

|

1. Assembled by the frame, hydraulic controller, planning tool, support of planning tool & the heating plate, the heating plate and the optional accessories;

2. Independent temperature control of the heating plate and PTFE surface coating;

3. Heating control with precision and stable electronic temperature control device, and provide the deviation correction function;

4. Electric planning tool;

5. Main body of Frame is Aluminium alloy. 45° inclined design, simple structure and easy to use;

6. Hydraulic control frame, more powerful and low starting pressure to make the small diameter pipe welding is more reliable;

7. Welding position can be transformed. Convenient to weld all kinds of pipe fittings;

8. Independent dual channel timer can record the two periods of heat and cooling, timing alarm over to convenient the user;

9. Big dial, high-precision shock pressure, table read mathematical clearly;

10. All of the sealing ring and joint device were imported from the international famous brand.

1. Flange welding special liners

2. Layer liners

3. Data logger(Need to use Ⅱ type hydraulic control unit)

4. Hot plate automatic popup device

5. Planning tool flip device

6. HDPE/PVC Pipe roller(20-2000mm)

7. HDPE/PVC pipe cutter(Electric Cutting Machine or Manual cutter)

8. Moving trailers(Suitable for large diameter welding machine)

|

|

|

|

|

|

|

|

All products will be tested before packing to ensure that the machine is in good condition, normal operation, and debugging to normal usage of the state.

12 Months for our welding machine under normal using conditions.

All the parts of our welding machine could be replaced by 80% of the original parts cost after warranty period.

All welding machine & part will be packaged by the export standard plywood case to protect the welding machine and all part against damage.

1. Shipped by Air for urgent requirements.

2. Shipped by LCL container service for less then one container, without any other requirements.

3. Shipped together with our HDPE/PVC pipe and fittings in the container.

4. Shipped together with your other products you ordered from China.

|

|

|

|

|

Major Parameter of 63-160mm Hydraulic Butt Fusion Welding Machine |

|||

|

BFY160 |

Includes basic fra me, planing tool, heating plate, hydraulic unit, stand and trolly |

||

|

Fusion Range |

Dia: 63 75 90 110 125 140 160 |

Package(mm) |

|

|

Butting Deviation |

≤ 0.3mm |

Basic Frame |

Wooden Case 885X475X500 |

|

Temperature Deviation |

±3°C |

Hydraulic Unit |

Wooden Case 495X565X520 |

|

Total Section of Cylinders |

15.3CM² |

Total Volume (CBM) |

0.6CBM |

|

Heating plate Max Temperature |

299°C |

G.W. ( Total) |

112.5KG |

|

Operation Pressure Range |

0-4MPa |

Power(W) |

|

|

Applicable Material |

PE/PP-R/PB/PVDF/PP/MPP |

Heating Plate |

1.6KW/220V |

|

Ambient Temperature |

-5~40°C |

Planing Tool |

0.68KW/220V |

|

Required Time for Welding Temperature |

< 20min |

Hydraulic Unit |

0.75KW/220V |

|

Power Plug |

Option for EN, EU, US standard. |

||

|

MOQ: 1 Set is available. |

|||

|

Major Parameter of 63-200mm Hydraulic Butt Fusion Welding Machine |

|||

|

BFY200 |

Includes basic fra me, planing tool, heating plate, hydraulic unit, stand and trolly |

||

|

Fusion Range |

Dia: 63 75 90 110125 140 160 180 200 |

Package(mm) |

|

|

Butting Deviation |

≤ 0.3mm |

Basic Frame |

Wooden Case 885X475X500 |

|

Temperature Deviation |

±3°C |

Hydraulic Unit |

Wooden Case 495X565X520 |

|

Total Section of Cylinders |

15.3CM² |

Total Volume (CBM) |

0.6CBM |

|

Heating plate Max Temperature |

299°C |

G.W. ( Total) |

120KG |

|

Operation Pressure Range |

0-4MPa |

Power(W) |

|

|

Applicable Material |

PE/PP-R/PB/PVDF/PP/MPP |

Heating Plate |

2.0KW/220V |

|

Ambient Temperature |

-5~40°C |

Planing Tool |

0.68KW/220V |

|

Required Time for Welding Temperature |

< 20min |

Hydraulic Unit |

0.75KW/220V |

|

Power Plug |

Option for EN, EU, US standard. |

||

|

MOQ: 1 Set is available. |

|||

|

Major Parameter of 63-250mm Semi-Automatic Hydraulic Butt Fusion Welding Machine |

|||

|

BFY250 |

Includes basic fra me, planing tool, heating plate, hydraulic unit, stand and trolly |

||

|

Fusion Range |

Dia: 90 110 125 140 160 180 200 225 250 |

Package(mm) |

|

|

Butting Deviation |

≤ 0.3mm |

Basic Frame |

Wooden Case 900X580X460 |

|

Temperature Deviation |

±3°C |

Hydraulic Unit |

Wooden Case 770X550X615 |

|

Total Section of Cylinders |

11CM² |

Total Volume (CBM) |

0.7CBM |

|

Heating plate Max Temperature |

299°C |

G.W. ( Total) |

146KG |

|

Operation Pressure Range |

0-4.5MPa |

Power(W) |

|

|

Applicable Material |

PE/PP-R/PB/PVDF/PP/MPP |

Heating Plate |

2.55KW/220V |

|

Ambient Temperature |

-5~40°C |

Planing Tool |

1.0KW/220V |

|

Required Time for Welding Temperature |

< 20min |

Hydraulic Unit |

0.75KW/220V |

|

Power Plug |

Option for EN, EU, US standard. |

||

|

MOQ: 1 Set is available. |

|||

HDPE Pipe And Fittings Butt Fusion Welding Machines Provided By Us Are Extensively Used In Different Hdpe Pipeline Construction Projects Or Workshop.

|

|

| HDPE Electrofusion Machine For Water Pipes | HDPE Electrofusion Machine For Gas Pipes |

|

|

| HDPE Butt Fusion Machine For Water Supply Pipes | HDPE Butt Fusion Machine For Gas Pipes |

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.