Contact Info

16-513, North Fangcheng District 2, Southwest Corner of the Intersection of Miyun Road and Huanghe Road, Nankai District, Tianjin, China

Dingrunda's PE Steel Belt Reinforced Pipes provide a reliable and efficient solution for applications that demand robustness and resilience against external pressures.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

The steel belt reinforced PE corrugated pipe is formed with polyethylene as its inner and outer layer base material and a steel belt that is coated with resin as the main support structure which are fused into a single spiral construction by a winding and extrusion process on the production line. This product contains the advantages of steel high rigidity, high strength, and exceptional corrosion resistance, wear resistance and flexibility. The pipe does not only achieve certain values of ring stiffness, but also cater for the corrosion aspect of the steel material and address the ring stiffness limitations posed by the large diameter pipe.

01 Using PE as anti-corrosion material, will not be corrupted by acid and oil in sewage and wastewater.

02 Even in the environment of 60℃ below zero, the pipe will not freeze to broken or leaking.

03 Connection mode is diversity and simple, simple and rapid construction at the scene.

04 The product is flexible, external impact, restoring performance is superior when external impact occur, the foundation settlement case is not easy to break.

05 The pipe base material can effectively use more than 50 years in 20℃, strong aging resistance.

06 Pipe is light, convenient connection, the excavation engineering requirement is not high, in the city drainage engineering construction, save the project time and cost a lot.

07 Pipe weight is only 1/8 of the concrete pipe and two-thirds of traditional winding plastic tube structure, easy to transport, construction is convenient, do not need to use large construction equipment.

08 Pipe friction coefficient is low, strong medium conveying ability.

09 Rubber inside is smooth, smal friction resistance, fast drainage.

HDPE pipe, constructed from high-density polyethylene, boasts impressive features such as corrosion resistance, high tensile strength, exceptional wear resistance, and robust impact resistance. Due to these qualities, it finds extensive application in various sectors including water supply, drainage systems, gas transmission, the chemical industry, and petroleum. Recognized for its reliability, durability, and cost-effectiveness, HDPE pipe stands as a preferred choice. Additionally, Dingrunda offers a diverse range of pipes, encompassing water supply and drainage pipes, silicon core pipes, steel mesh skeleton pipes, and dredging pipes, tailored to meet the distinct requirements of various pipeline systems, ensuring efficient and practical solutions.

|

ND/ID(mm) |

Dim.min (mm) |

Emin(mm) |

Emin(mm) |

Pmax(mm) |

Tmin(mm) |

E2min(mm) |

|

300 |

294 |

2.5 |

4.0 |

75 |

0.4 |

2.2 |

|

400 |

392 |

3.0 |

4.5 |

85 |

0.4 |

2.2 |

|

500 |

490 |

3.5 |

5.0 |

100 |

0.5 |

2.5 |

|

600 |

588 |

4.0 |

6.0 |

110 |

0.5 |

2.5 |

|

700 |

685 |

4.5 |

6.0 |

115 |

0.5 |

2.5 |

|

800 |

785 |

5.0 |

7.0 |

120 |

0.7 |

3.0 |

|

900 |

885 |

5.0 |

7.5 |

135 |

0.7 |

3.0 |

|

1000 |

985 |

5.0 |

8.0 |

150 |

0.7 |

3.0 |

|

1100 |

1085 |

5.0 |

8.0 |

165 |

0.7 |

3.0 |

|

1200 |

1185 |

5.0 |

8.0 |

180 |

0.7 |

3.0 |

|

1300 |

1285 |

5.0 |

8.0 |

210 |

0.4 |

3.0 |

|

1400 |

1385 |

5.0 |

8.0 |

210 |

1.0 |

3.0 |

|

1500 |

1485 |

5.0 |

8.0 |

220 |

1.0 |

3.0 |

|

1600 |

1585 |

5.0 |

9.0 |

230 |

1.0 |

3.5 |

|

1800 |

1785 |

5.0 |

9.0 |

230 |

1.0 |

3.5 |

|

2000 |

1985 |

6.0 |

9.0 |

235 |

1.0 |

3.5 |

|

2200 |

2185 |

6.0 |

9.0 |

235 |

1.2 |

3.5 |

|

2400 |

2385 |

6.0 |

10.0 |

235 |

1.2 |

3.5 |

|

Item |

Typical Value |

|

Ring Stiffness (KN/m2)SN16 |

≥16 |

|

SN12.5 |

≥12.5 |

|

SN8 |

≥8 |

|

TIR |

≤10 |

|

Ring Flexibility |

no rupture,no withdraw in two walls |

|

Creep Proportion |

≤ 2 |

|

Peel strength(20℃±5℃)/N/cm |

≥100 |

|

Drying Test Chamber |

No delamination,no |

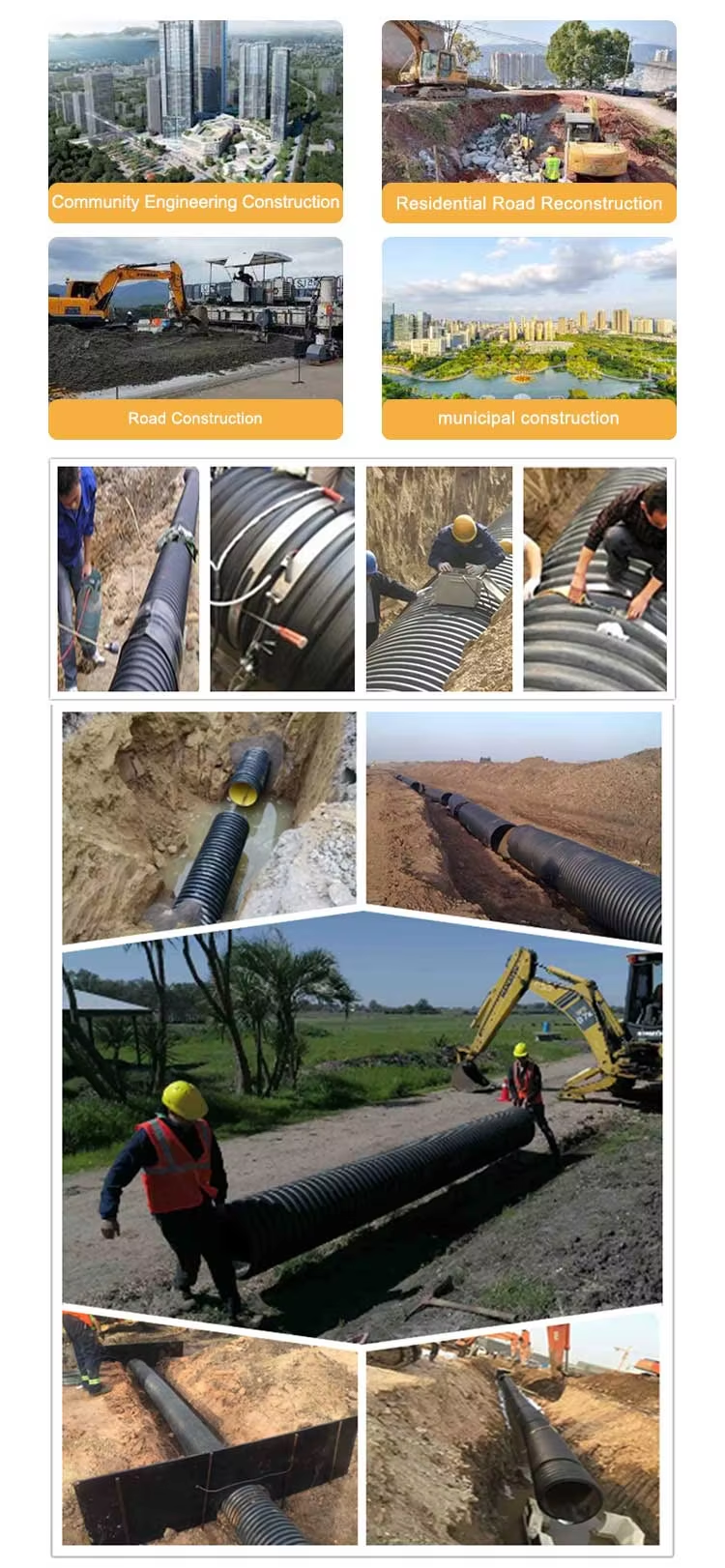

1. The application field of steel belt Reinforced PE corrugated pipe.

2. Steel belt reinforced PE bellows application field.

3. Municipal engineering: buried drainage, sewage pipe.

4. Road engineering: seepage and drainage of railways and highways.

5. Industry: Sewage pipes widely used in industrial fields.

6. Construction works: building rainwater pipes, underground drain pipes, sewage pipes, ventilation pipes, etc., landfill sewage collection pipes.

7. Large port, dock project: drainage, sewage pipe, etc. for large airports, ports and docks.

8. Sports venues: water seepage drainage pipes for sports venues such as golf courses and football fields.

9. Water conservancy projects: use of water source pipes, irrigation pipes and water and drainage of hydropower stations.

10. Mine: mine ventilation, air supply, drainage, mud pipe.

11. Communication tube: railway, highway communication, communication cable, cable protection tube.

12. Water storage system: a water storage system that traps slow water flow.

13. Agricultural engineering: farmland, orchard, tea garden and forest belt drainage and seawater transportation pipe.

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.