Contact Info

16-513, North Fangcheng District 2, Southwest Corner of the Intersection of Miyun Road and Huanghe Road, Nankai District, Tianjin, China

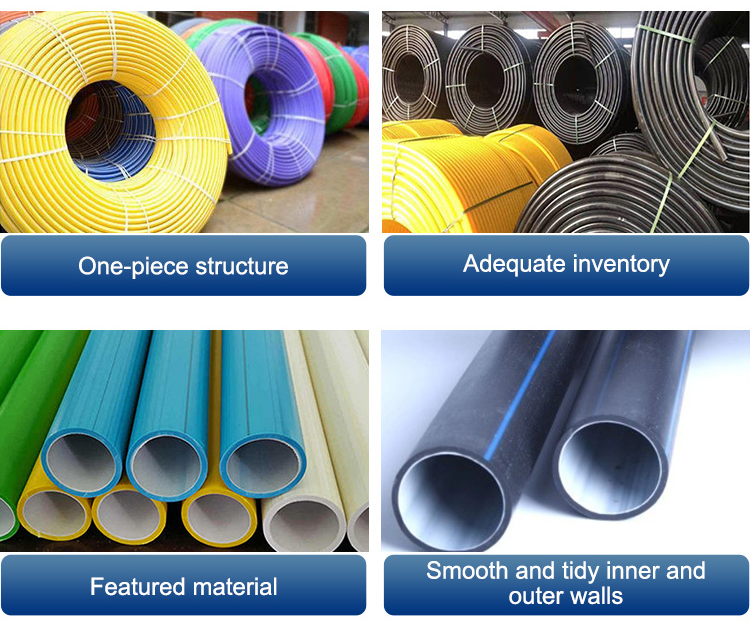

Dingrunda's HDPE Silicon Core Pipes offer a reliable and efficient solution for protecting and routing fiber optic cables in various communication systems.

HDPE silicon core pipes is a new type of composite pipes with a silicon solid lubricant inner wall. It have good dealing performance, chemical corrosion resistance and low engineering cost. It is widely used in optical fiber cable communication network system for highways and railways.

01.Silicon core pipe is a new kind of composite pipe with silicone solid lubricant in inner wall, which be widely used in optical communication network system of highway, railway, etc.

02.Adopt the mode of multi-machine co-extrusion, silicon core layer is synchronizely embeded in the pipe. It will be lubricated and not be stripped forever.

03.The friction coefficient of the inner wall is very small. Optical cable (electric cable) can be repeatedly extracted and tensioned in the pipe. By using cable blowing machine, one time blowing length can be 1000 to 2000 meter under normal conditions.

04.Waterproof, damp-proof, can avoid the damage by rodent animals.

05.With great ring siffness and toughness. In construction, its bending radius should not be less than 10 times of the external diameter of the pipe.

01.Silicon core pipe is a new kind of composite pipe with silicone solid lubricant in the inner wall, which is widely used in optical communication network systems of highways, railways, etc.

02.Adopting the mode of multi-machine co-extrusion, the silicon core layer is synchronously embedded in the pipe. It remains lubricated and will never be stripped.

03.The friction coefficient of the inner wall is very small. Optical cables (electric cables) can be repeatedly extracted and tensioned within the pipe. By using a cable blowing machine, the one-time blowing length can be 1000 to 2000 meters under normal conditions.

04.Waterproof, damp-proof, and resistant to damage by rodent animals.

05.With great ring stiffness and toughness. In construction, its bending radius should not be less than 10 times the external diameter of the pipe.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

01 Silicon core pipe is a new kind of composite pipe with silicone solid lubricant in the inner wall, which is widely used in optical communication network systems of highways, railways, etc.

01.Silicon core pipe is a new kind of composite pipe with silicone solid lubricant in the inner wall, which is widely used in optical communication network systems of highways, railways, etc.

02.Adopting the mode of multi-machine co-extrusion, the silicon core layer is synchronously embedded in the pipe. It remains lubricated and will never be stripped.

03.The friction coefficient of the inner wall is very small. Optical cables (electric cables) can be repeatedly extracted and tensioned within the pipe. By using a cable blowing machine, the one-time blowing length can be 1000 to 2000 meters under normal conditions.

04.Waterproof, damp-proof, and resistant to damage by rodent animals.

05.With great ring stiffness and toughness. In construction, its bending radius should not be less than 10 times the external diameter of the pipe.

02 Adopting the mode of multi-machine co-extrusion, the silicon core layer is synchronously embedded in the pipe. It remains lubricated and will never be stripped.

03 The friction coefficient of the inner wall is very small. Optical cables (electric cables) can be repeatedly extracted and tensioned within the pipe. By using a cable blowing machine, the one-time blowing length can be 1000 to 2000 meters under normal conditions.

04 Waterproof, damp-proof, and resistant to damage by rodent animals.

05 With great ring stiffness and toughness. In construction, its bending radius should not be less than 10 times the external diameter of the pipe.

06 Aging-resistant and chemically anticorrosive. With a long service life, it will not deteriorate within 50 years when buried in the earth.

07 Convenient for construction. This will save time and the project cost less than 70% of the PVC electronical pipe.

HDPE pipe, constructed from high-density polyethylene, boasts impressive features such as corrosion resistance, high tensile strength, exceptional wear resistance, and robust impact resistance. Due to these qualities, it finds extensive application in various sectors including water supply, drainage systems, gas transmission, the chemical industry, and petroleum. Recognized for its reliability, durability, and cost-effectiveness, HDPE pipe stands as a preferred choice. Additionally, Dingrunda offers a diverse range of pipes, encompassing water supply and drainage pipes, silicon core pipes, steel mesh skeleton pipes, and dredging pipes, tailored to meet the distinct requirements of various pipeline systems, ensuring efficient and practical solutions.

|

Specification |

OD(mm) |

Min ID(mm) |

Tickness(mm) |

Length(m) |

Elasticity |

|

|

Before coiling |

After coiling |

|||||

|

32/26 |

32 |

26 |

2.5 |

1000,2000,3000 |

≤2 |

≤3 |

|

34/28 |

34 |

28 |

3.0 |

1000,2000,3000 |

≤2 |

≤3 |

|

40/33 |

40 |

33 |

3.5 |

1000,2000,3000 |

≤2.5 |

≤3.5 |

|

46/38 |

46 |

38 |

4.0 |

1000,1500 |

≤3 |

≤5 |

|

50/41 |

50 |

41 |

4.5 |

1000,1500 |

≤3 |

≤5 |

|

63/54 |

63 |

54 |

5.0 |

1000,1500 |

≤3 |

≤5 |

01 The optical cable of installation and protection.

02 Communication pipeline on highway and rail way.

03 Others’ communication project pipeline.

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.