Contact Info

16-513, North Fangcheng District 2, Southwest Corner of the Intersection of Miyun Road and Huanghe Road, Nankai District, Tianjin, China

Dingrunda's HDPE Pipes for Aquaculture Cages ensure a strong and stable foundation for fish farming, contributing to the health and productivity of aquaculture enterprises.

1.Delivery: 10-30 days depending on the total quantity.

2.Packing: 11.8m or 5.8m/ Pcs for straight, 100-200m by coils for DN20-90mm.

3.CO (Certificate of Origin): China, CO could be provided by free

4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

5.MOQ: Trial Order or 1*20ft containers by mixed loading.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

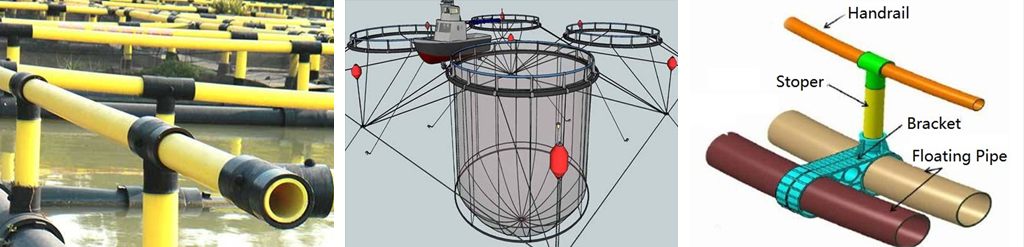

Floating Pipe: The Key part of the pipe, two of a complete Fish cage, inside can be filled with foam which strengthen the Buoyancy

Handrail Pipe: higher than the floating pipe and water level, can be held by fisherman while feeding or fishing.

Bracket: usually every 2 meters of 1 pc, major part of supporting the fish cage structure, including L shape Bracket, triangle bracket, one-hole bracket and two-holes bracket etc., each has different features and advantages.

Walkway Decking: equipped for more convenient for feeding or fishing, can also be replaced by plank, not a must of a fish cage.

Pipe for the Walkway Decking: there are two small holes both in the bracket and the walkway decking, while two small pipes can combine the bracket and walkway decking to make it stronger.

Secondary Pipe: make the fish cage more stable.

Foam inside the floating pipe: usually only the inside floating pipe will use the foam to add Buoyancy.

Pin: combine the handrail pipe and bracket, also the bracket and floating pipe.

Stopper: being used at both side of bracket which give a swing space for the bracket. As storm and ocean current, a little space for bracket can bring more elasticity and longer life span for the fish cage.

The fish nets are made of polyethylene or nylon material. Both are with outstanding chemical stability and mechanical performance. Polyethylene is cost-effective and nylon is with longer lifespan.

The module includes but not limited to predator net, inner net, and cover net for birds.

The mooring system is a highly customized module, depending on wind, waves, currents, water depth and seabed.

The module includes but not limited to anchors, ropes, chains, sinker, warning light, rings, and accessories.

It includes the tools and welding machines to connect the pipes and fittings together, to make sure the strong enough of the whole HDPE cages system.

Polyethylene net includes inner net, outer net, and cover net (bird-proof net). It is made of nylon, polyethylene, and ultra-high molecular weight meshes treated by anti-ultraviolet technology with international weaving technology. The net has high strength, good safety, long service life, and according to customer needs, the net can be treated with anti-adhesion, which ensures that the effective anti-adhesion time of the net is prolonged by more than half a year under normal conditions and reduces the frequency of manual screen replacement. In addition, the underwater molding system designed by the company can effectively reduce the floating of the net and effectively raise more than 90% of the water body.

High intensity

Excellent flexibility

Corrosion resistant

Carbon black and antioxidants are added to the raw materials, with good UV resistance and antioxidant ability.

Strongly resistant to the storm

Long service life

Sufficient aquaculture volume with high efficiency and low comprehensive cost

Less pollution and high grade aquaculture water resulted in the perfect quality of the fish products, the good benefits and high returns.

Cage technology can not only be used for aquaculture(fish farming) in various water environments such as reservoirs, shallow seas, deep seas, harbors, lakes, etc., it can also be used for docks, hydropower stations, water parks, beaches, etc. In the shipbuilding industry, it is used to build small boats and rowing boats with simple structures. In tourism, leisure and entertainment, it is used to build various water platforms, water parks and various swimming pools.

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.