Contact Info

16-513, North Fangcheng District 2, Southwest Corner of the Intersection of Miyun Road and Huanghe Road, Nankai District, Tianjin, China

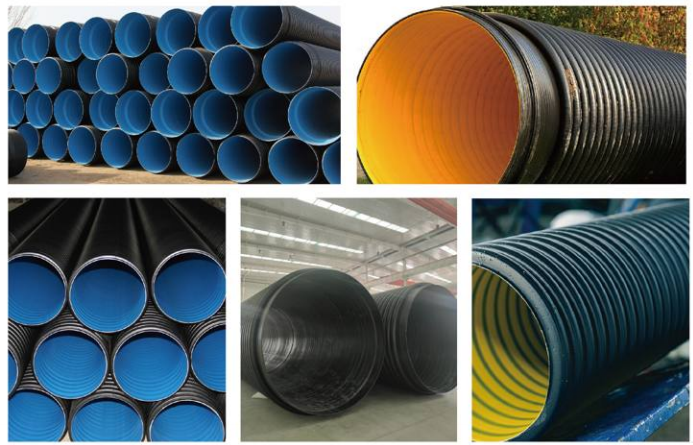

HDPE Double Wall Corrugated Sewage Pipe is made of high density polyethylene, which is co-extruded by inner and outer extruders respectively and formed in one step. The inner wall is flat and smooth, and the outer wall is corrugated. It has an annular outer wall with a hollow layer between the inner and outer walls. It has unique structure and high strength.The whole production process is: extrusion-compounding-molding-cooling-cutting-finished product.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

1. It has the characteristics of light weight, high ring stiffness, convenient construction, transportation and installation, low installation cost, high ultraviolet resistance stability and good flexibility etc.With appropriate bending degree, HDPE double-wall corrugated pipe with a certain length can be slightly bent.Because of the uneven foundation in use, the pipe can be bent naturally which cannot make leakage.Compared with other pipes in same diameter, the flow rate of HDPE double-wall corrugated pipe is higher because of its smooth inner wall.Meanwhile,it has the characteristics of unblocked, easy maintenance,pressure resistance, low temperature resistance, high impact strength, acid and alkali resistance, corrosion resistance and long service life and so on.

2. Reasonable structure and excellent performance: HDPE double-wall corrugated pipe adopts annular structure wall pipe and optimized corrugated structure, so that the pipe has greater strength and appropriate flexibility per unit weight, which makes the raw material more efficient. After years of production and practice,the production technology is reliable and the product performance is stable.

3. Reliable connection to prevent leakage:HDPE double-wall corrugated pipe adopts reinforced design in socket and it is connected with sealing rubber ring which makes the pipe more firm and reliable before and after connection.And the strict control of the size of the socket joint makes the installation more convenient and leakage prevention more effective.

4. Implement the standard "Buried Polyethylene (PE) Structural Piping System Part I: Polyethylene Double Wall Corrugated Pipe" GB/T19472.1-2004

Connection Methods

HDPE Double Wall Corrugated Sewage Pipe Installation and Connection Instruction

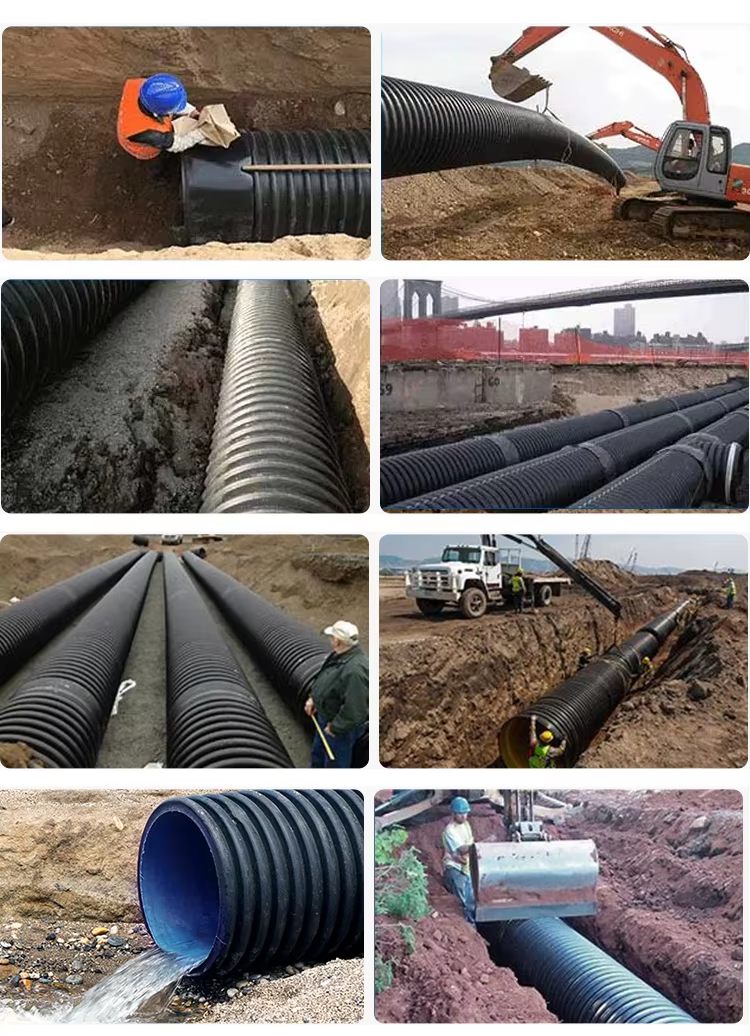

1. The pipeline shall be laid on undisturbed soil foundation or backfilled and compacted stratum after slotting. The thickness of soil covering on the top of the pipeline under the roadway shall not be less than 700 mm.

2. HDPE double wall corrugated pipe can be installed in the same groove,and can be carried out according to the relevant regulations for the design and construction of common pipelines laid in the same groove.

3. When the pipeline passes through railways, high-grade road embankments and structures with obstacles,the protective pipe sleeves made of reinforced concrete, steel, cast iron and other materials shall be provided. The inner diameter of the sleeve shall be above 300mm larger than the outer diameter of the corrugated pipe, and the space between the corrugated pipe and the sleeve shall be filled with filler.

4. The width of the bottom in the groove should be determined by adding 600mm to the outer diameter of the pipe so as to facilitate manual operation at the groove bottom.

5. The slotted length should be shortened as much as possible when installation in rainy days. Slot and backfill quickly and make prevention measurements of filling with water. In case of filling with water, water shall be removed as well as the softened soil layer affected by water.Basic treatment should be made with sand and gravel or medium coarse sand.

6. The pipeline foundation design adopts cushion foundation. When the bottom of the groove is below the groundwater level, it is advisable to lay a layer of gravel or crushed stone with a thickness of no less than 150 mm and the size of gravel is 5-40 mm, and then lay a sand cushion (medium and coarse sand) with a thickness of no less than 50 mm and a total thickness of no less than 200 mm.

7. Pipeline installation can be generally installed manually. During installation, both ends of the pipeline are manually lifted to the personnel in groove. In open groove, non - metallic rope pipe is used when the groove depth is larger than 3m or pipe diameter is larger than 400mm,and make the pipe smoothly in the groove. It is strictly prohibited to hook both ends with metal ropes or throw the pipe into the groove directly. For mixing groove or support groove,it is advisable to handle the pipe intensively from one end of the groove, and transport the pipe to the installation position at the bottom of the groove.

8. Socket-ended pipe installation should be made from downstream to upstream installation in turn,with straight pipe end along the direction of water flow and socket end in reverse direction of water flow.

9. Pipe length can be cut by hand saw without roughness and damage in cutting section.

10. The following regulations shall be observed when rubber ring is used to seal the joint:

(1)Check whether the rubber ring is suitable before connection and confirm the position placed and socketed depth.

(2)Clean the socket end with cotton cloth without any soil left before connection, coat with lubricant,and aim at the straight pipe end immediately.

(3)Insert the straight pipe end into the socket end.Arrange a wooden baffle at the end of the pipe and push the pipe slowly with a crowbar.When size larger than 400mm, fasten the pipes with flexible rope, insert with manual lifting tools and construction machinery is strictly prohibited.

|

Diameter(mm) |

100,150,200,225,300,400,500,600,700,800 |

|

Materials |

Polyethylene |

|

Ring Stiffness |

SN4, SN8, S1S2 |

|

Color1 |

Both outside and inner surface are black. |

|

Color2 |

Outside surface is black, inner surface is blue. |

|

Color3 |

Outside surface is black, inner surface is yellow. |

|

Fittings offered |

Rubber ring,or coupler |

|

OEM |

OEM services is available |

|

Loading method |

The best way is to load the smaller size into larger size to load |

|

|

|

|

Item |

Inde |

|

Ring stiffness SN4(kN/m2) |

≥4 |

|

Ring stiffness SN8(kN/m2) |

≥8 |

|

Impact strength(%) |

≤10 |

|

Ring suppleness |

The sample is smooth without any recurvation or wall loose. |

|

Oven experiment |

No delamination and no crack. |

|

Creep rate |

≤4 |

01 Municipal engineering project.

can be used for drainage and sewerage pipe.

02 Construction project.

Can be used for building rain water pipe, storm sewer, and underground drainage pipe, sewage pipe,etc.

03 Electrical telecom engineering project.

Can be used for all kinds of power cable protection conduit.

04 Industrial project.

Widely used as drainage and sewerage pipe in chemical, medicine, environmental industries.

05 Agriculture and garden projects.

Can be used as irrigation pipe, sewerage and drainage pipe for farmland and, garden, tea garden,.treelawn and forest.

06 Road engineering project.

Can be used as seepage pipe, sewerage and drainage pipe for railway and highway.

07 Mining engineering project.

Can be used as ventilation pipe, air supply pipe and drain pipe.

08 HDPE perforated double-wall corrugated pipe with holes.

can be used as water penetration pipe and drain pipe for saline-alkali land and the highway.

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.