Contact Info

16-513, North Fangcheng District 2, Southwest Corner of the Intersection of Miyun Road and Huanghe Road, Nankai District, Tianjin, China

GRPpipeline is a New composite materials, which based on resinas unsaturated resin or vinyl ester resin, Glass fiber Reinforced material.

It is the best choice in Chemical industry, water supply and drainage projects and pipeline project, which have good Corrosion resistance, low water resistance characteristics, lightweighthigh

strength, high transport flow, easy installation, short construction period and low comprehensive invest-ment andother excellentd performances.

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

Chemical corrosion resistance, long service life.

FRP has special chemical corrosion resistance, and its pipeline products are suitable for conveying various acids, alkali, salt and organic solvents and other different meda.

Excellent water conservancy characteristics.

Water conservancy characteristics are one of the main characteristics of FRP pipeline. Excellent hydraulic characteristics mean that the loss of fluid head is small, and the pump with smaller diameter or lower power can be selected, thus reducing the initial investment of pipeline engineering, saving electricity and reducing operating costs.

The inner surface of FRP pipe is quite smooth, and the general surface roughness rate can be 0.008, which can almost be considered as "hydraulic smooth pipe". In the process of operation, the inner surfaces of steel pipes, cast iron pipes and cement pipes often corrode locally and become rougher and rougher, while glass steel pipes always keep the surface of new pipes smooth.

Good design flexibility and short modification period.

Fiberglass reinforced pipe is formed by winding fiber-reinforced materials impregnated with resin matrix layer by layer on the mandrel according to specific technological conditions and curing it properly. The pipe wall is a layered structure. The physical and chemical properties of fiberglass reinforced pipe can be adjusted by changing the resin system or adopting different reinforcing materials to adapt to different media and working conditions to make fiberglass reinforced pipe with different pressure levels or certain special properties. Short modification periodic remarkable feature of fiber-wound composites, which can't be compared with all kinds of metal pipes with the same properties.

Low Cost of installation and maintenance.

There is no need for special anti-corrosion treatment for FRP pipes, the insulation layer can be thinned or even not treated, the pipes are lighter, the tonnage of hoisting equipment is small, the power consumption is less, the length of glass steel pipes is longer than that of castiron cement pipes, and the number of joints is relatively reduced, which will reduce the installation and maintenance costs, which has been proved by many engineering practices at home and abroad.

Excellent Physical properties.

The proportion of glass tube material is usually 1.8-2.1g/cm3, about 1/4 to 1/5 of steel, higher strength than steel, cast iron and plastic.

The weight of FRP/GRP is no more than 1/3 of steel pipe under the same specification, and its physical properties are excellent. In addition, some physical properties of glass steel pipe are quite superior, and its thermal expansion coefficient is roughly equivalent to that of steel. Its thermal conductivity is only 0.5% of the steel. It is a good thermal and electrical insulator.

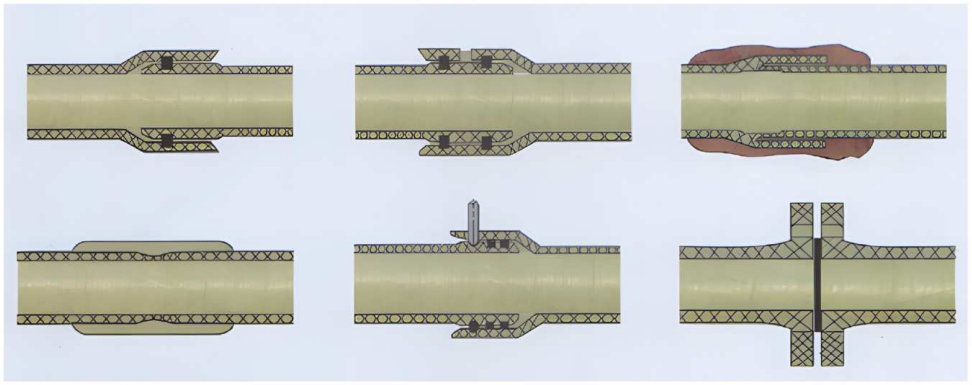

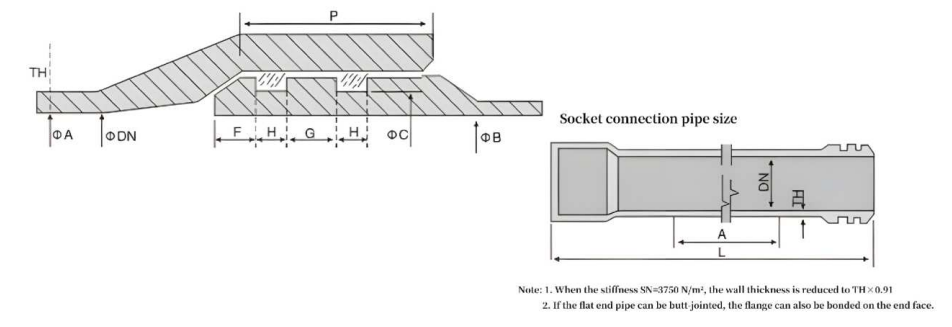

Pipeline Connection.

The whole pipe has been pressure tested before leaving the factory. On-site testing only requires testing whether the double rings of the interface are sealed. It only takes 15 minutes to install a Ф800-Ф1000mm pipe, including the joint pressure test. The FRP flange connection size can be matched with HG, JB, GB, ASTM, DIN, NF, JiS and other standards. The connection method between FRP pipes andother pipes can also be socket, joint, special adhesive and other methods.

|

Fabrication technics |

Winding process |

|

Material |

resin,Glass fiber Reinforced material,Curing agent,Cobalt |

|

Pipe Diameter(mm) |

DN50-DN5000 |

|

Pipe Length(m) |

6m/12m |

|

Pressure Grade |

0.1MPa,0.6MPa,1.0MPa,1.6MPa,2.0MPa,2.5MPa |

|

Stiffness Grade |

SN1250,SN2500,SN5000,SN10000 |

|

Connection Method |

bell and spigot joint,bonded joint,flange joint and so on |

Physical and other performance parameters of FRP/GRP

|

HBI-A |

40 |

Surface resistivity |

25x1011Ω |

|

Cypress coefficient |

0.3 |

Roughnessrate of inner surface |

0.0084 |

|

Fracture elongation |

0.8% |

Food-grade residual nuit content |

200ppm |

|

oxygen index |

30% |

PVC-FRP layer Actual shear strength |

7Mpa |

|

volume resistivity |

55x1014Ω .cm |

||

01. Residential cold and hot water system.

02. Underground heating system.

03. Conveyor of industrial water and chemical material.

04. Sanitary and pure water.

05. Hot water recycling system.

06. Compressed air pipeline.

07. Drink manufacturing and conveying system.

08. Other industrial and agricultural pipeline.

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.