Contact Info

16-513, North Fangcheng District 2, Southwest Corner of the Intersection of Miyun Road and Huanghe Road, Nankai District, Tianjin, China

HDPE pipe and fittings welding machines provided by us are extensively used in different HDPE pipeline construction projects.

♦ Welding Range in mm: 63mm-1200mm

♦ Welding Range in inch: 2inch -48inch IPS

♦ Power Supply: 220v, 380v/ 50-60HZ

♦ MOQ 1 set

♦ Discounts for bulk orders

♦ Terms of Payment: T/T, West Union

OEM / ODM

7 *24-Hour service

After-sales

Introduction

Parameter

Application

The HDPE butt fusion welding machine is a highly efficient and reliable tool used for joining High-Density Polyethylene (HDPE) pipes. It offers several notable features that make it an ideal choice for various applications.

1. Versatility: The machine is designed to fuse HDPE pipes of different sizes, ranging from small to large diameters.

2. User-friendly: The machine is easy to operate, making it suitable for both experienced professionals and beginners. It typically includes clear instructions and intuitive controls, ensuring a hassle-free welding experience.

3. Durability: Made from high-quality materials, the machine is built to withstand harsh working conditions and heavy-duty usage. It is resistant to corrosion, wear, and tear, ensuring long-lasting performance and minimal maintenance requirements.

4. Efficiency: The HDPE butt fusion welding machine offers a fast and efficient fusion process. It typically has a high heating capacity, allowing for quick heating and cooling cycles. This reduces the overall welding time, increasing productivity on the job site.

5. Safety: The machine incorporates various safety features to protect the operator and prevent accidents. These may include automatic temperature and pressure control systems, emergency stop buttons, and safety interlocks.

6. Cost-effective: By providing reliable and durable fusion joints, the machine helps reduce the need for repairs and replacements, resulting in cost savings over time. Additionally, its efficiency and productivity contribute to overall project cost reduction.

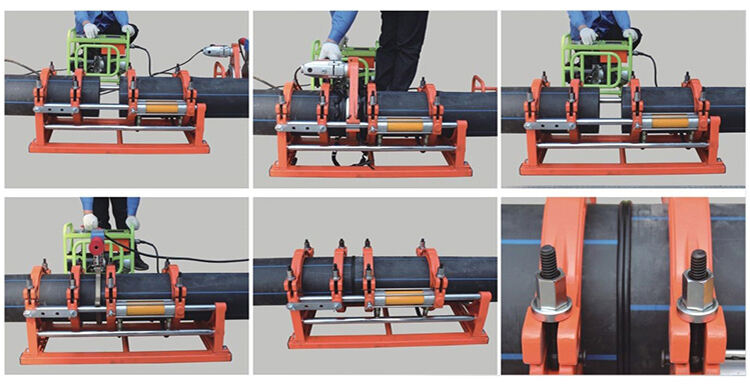

1. Material preparation: Pipes and pipe fittings should be matched with equal diameter, reducing elbow and tee fittings according to the construction requirements. Hot-melt welding should use pipe fittings of the same grade and material. Welding between pipe fittings of different grades and materials with similar performance should be tested first.

2. Clamp the pipe: Use a clean cloth to remove the dirt on the ends of the two pipes. Place the pipe in the rack slips, replace the basic fixture according to the pipe fittings to be welded, and select the appropriate slips so that the lengths of the two ends of the butt joint are approximately equal and should be as short as possible while meeting the requirements of milling and heating . The part of the pipe outside the frame is held up with a support frame, so that the axis of the pipe is at the same height as the center line of the frame, and then fastened with slips.

3. Cutting: Insert the milling cutter, then slowly close the welding ends of the two pipes, and apply appropriate pressure until continuous chips appear on both ends. Remove the pressure, wait a moment, and then exit the movable frame. The chip thickness should be 0.5~1.0mm to ensure that the impurities and oxide layers on the end faces of the welded pipe sections are cut, and the two butt joint end faces are smooth and clean.

4. Alignment: The wrong side of the two pairs of welded pipe sections should be as small as possible. If the wrong side is large, it will cause stress concentration, and the wrong side should not exceed 10% of the wall thickness.

5. Heating: After the temperature of the heating plate reaches the set value, put it into the rack and apply pressure until the minimum curling edge on both sides reaches the specified width and the pressure is reduced to the specified value to absorb heat. Ensure that there is enough molten material to prepare for the mutual diffusion of molecules during melting and docking.

6. Switching: The period from the end of heating to the beginning of the fusion docking is the switching period. To ensure the quality of the fusion docking, the shorter the switching period, the better.

7. Melting butt joint: It is the key to welding. The fusion butt joint process should always be carried out under the melting pressure.

8. Cooling: Due to the poor thermal conductivity of plastic materials, the cooling rate is correspondingly slow. The shrinkage of the weld material and the formation of the structure proceed at a slow speed over a long period of time. Therefore, the cooling of the weld must be carried out under a certain pressure.

|

Rack |

size(cm) |

82*44*40 |

85*48*44 |

85*53*43 |

94*62*60 |

|

weight (kg) |

38 |

42 |

52 |

80 |

|

|

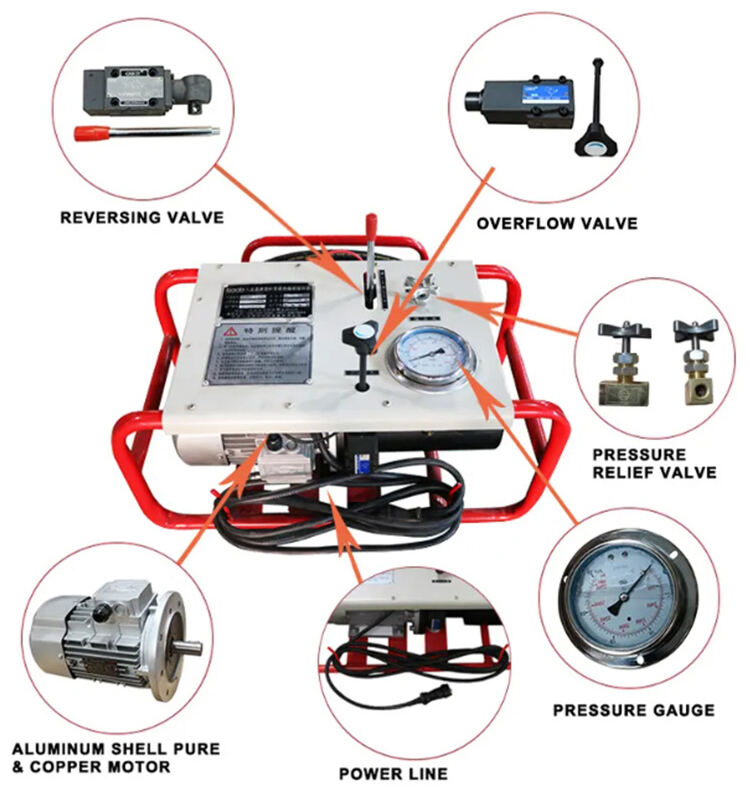

Hydraulic System |

size(cm) |

58*47*47 |

58*47*47 |

58*47*47 |

58*47*47 |

|

weight (kg) |

41.5 |

41.5 |

41.5 |

41.5 |

|

|

Cutter |

size(cm) |

31*24*32 |

35*36*35 |

36*47*47 |

59*38*58 |

|

weight (kg) |

6 |

7 |

17.5 |

22 |

|

|

Heating plate |

size(cm) |

37*5*35 |

37*5*40 |

44*5*47 |

44*5*53 |

|

weight (kg) |

3 |

3.8 |

5.5 |

7.8 |

|

|

Bucket |

size(cm) |

30*18.5*42 |

33.5*18.5*46 |

39*28*56.5 |

48*28.5*56.5 |

|

weight (kg) |

1.5 |

2.1 |

2.6 |

3.5 |

|

|

Total weight (kg) |

|

90 |

96.4 |

119.1 |

154.8 |

HDPE pipe welding machine Application:

HDPE Pipe Joint Welding Machine is Suitable for welding of plastic pipes and fittings made of PE,PP,PVDF and can be operated in any complex working condition.

HDPE pipe welding machine Features:

1. The machine body is equipped with four main clamps with the third clamp axially moved and adjusted.

2. Removable PTFE coated heating plate with separate temperature control system.

3. Electric milling cutter with reversible double cutting edge blades.

4. Hydraulic unit provides welding machine with compressing power.

5. Be made of lightweight and high strength material; simple structure and easy to operate.

6. Low starting pressure ensures reliable welding quality of small pipes.

7. Separate two-channel timer shows time in soaking and cooling phases.

8. High-accurate and shockproof pressure meter indicates clearer readings.

PE Pipe Welding Machine other names: But Fusion Welding Machine, Hotmelt Welding Machine, Hydraulic butt fusion welding machine. Hydraulic butt welding machine, HDPE butt fusion machine. Welding machine. Butt fusion Equipment. RDH315 HDPE Pipe Joint Welding Machine , Pipe Jointing Welding Machine, Poly welding machine. Plastic pipe fusion welding machine.

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.