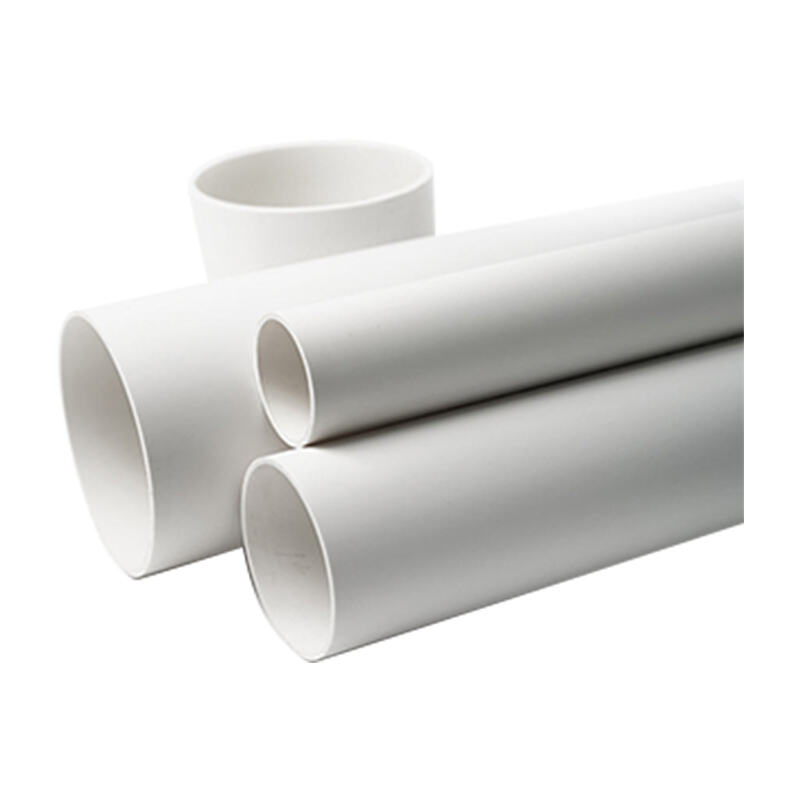

HDFE Pipes In Oil And Gas Applications

In the realm of oil and gas transportation, HDPE piping has emerged as a game-changer. Its utilization in a vast oilfield showcased its unparalleled advantages, transforming the efficiency and safety of the operation.

HDPE pipes, renowned for their corrosion resistance, played a pivotal role in ensuring the integrity of the transported oil and gas. This feature mitigated the risk of contamination, preserving the quality of the hydrocarbons throughout the distribution network. Additionally, their smooth interior walls minimized friction, optimizing flow rates and reducing energy consumption.

The pipes' exceptional durability was another key factor. Capable of enduring harsh environments and high pressures, HDPE piping provided a reliable infrastructure that reduced the need for frequent maintenance and repairs. This translated into cost savings and minimized downtime, enhancing the overall profitability of the operation.

Moreover, HDPE's eco-friendliness aligned with the industry's growing commitment to sustainability. Its recyclability and low environmental impact during production and installation minimized the carbon footprint, contributing to a greener future.

This exemplary case highlights the significant role HDPE piping plays in oil and gas applications. By ensuring product integrity, optimizing efficiency, and promoting sustainability, HDPE has become an indispensable component of modern hydrocarbon transportation.