HDPE Pipes in a Massive Desalination Plant Project

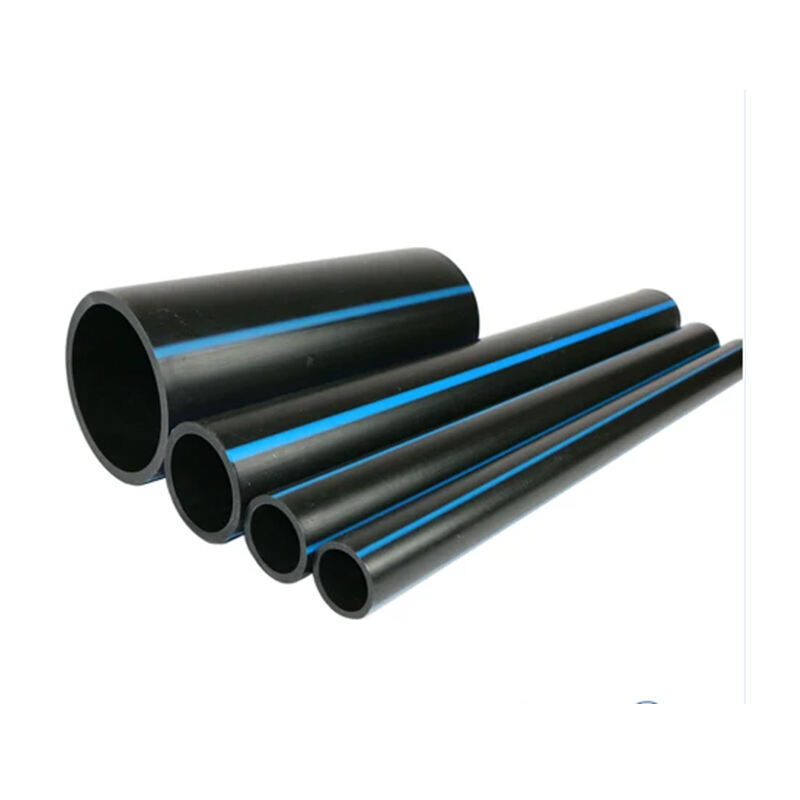

The construction of a massive desalination plant in a coastal region required the use of durable and reliable piping materials to handle the high volumes of seawater and desalinated water. High-density polyethylene (HDPE) pipes emerged as the ideal solution for this challenging project.

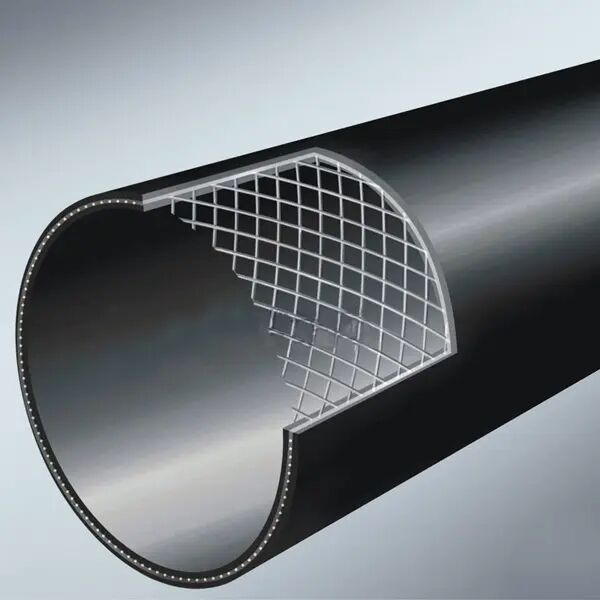

The desalination plant was designed to produce millions of gallons of freshwater daily, meeting the water needs of a rapidly growing urban area. The HDPE pipes were chosen for their excellent corrosion resistance, durability, and ability to handle high pressures. This was crucial as the pipes would be transporting seawater, which contains high levels of salt and other corrosive elements.

During the installation phase, the HDPE pipes were quickly and efficiently installed using fusion welding techniques. This ensured strong, leak-free connections that could withstand the rigorous demands of the desalination process. The pipes were also able to withstand the high temperatures and pressures encountered during the desalination process, ensuring reliable operation.

Once operational, the HDPE pipes proved to be a crucial component of the desalination plant. They efficiently transported the seawater to the desalination units and then distributed the desalinated water to the surrounding communities. The pipes' durability and corrosion resistance have allowed the plant to operate continuously with minimal maintenance requirements.

In conclusion, the use of HDPE pipes in this massive desalination plant project was a successful choice. Their excellent performance has contributed significantly to the plant's ability to provide a reliable source of freshwater to the surrounding communities.

RELATED PRODUCT

Write down your question

We are not only a product manufacturer, but also a solution provider. Whether you have questions or quotation requests, we will help you.