|

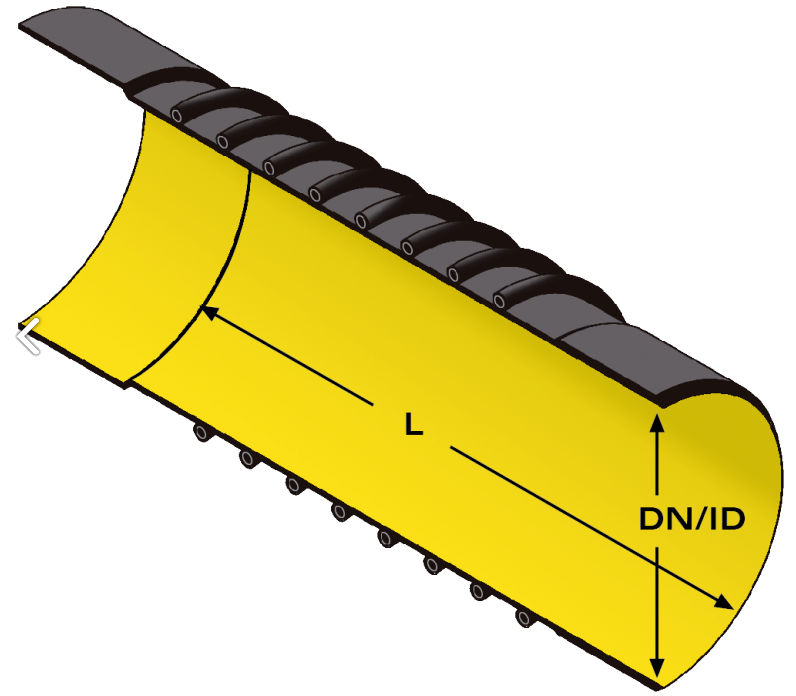

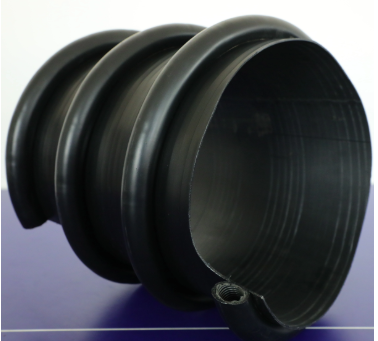

Krah pipe is a kind of special-shaped pipe with smooth inner wall and spiral strengthening outer wall. Spigot and socket Krah pipe normally divided into B type and C type, which are green and flexible, use high density polyethylene as raw material, produced by filament winding process in the states of hot-melt, gradually cooled by means of rolling air cooling and spraying in thermal state and before demolding. It is available for a wide range of diameters from 300 mm to 3000 mm, can be connected by socket-joint. Krah pipe has all the features: high strength, light weight, corrosion resistance, no leakage, good sealing and easy construction etc., be widely used in drainage projects. |

|

|