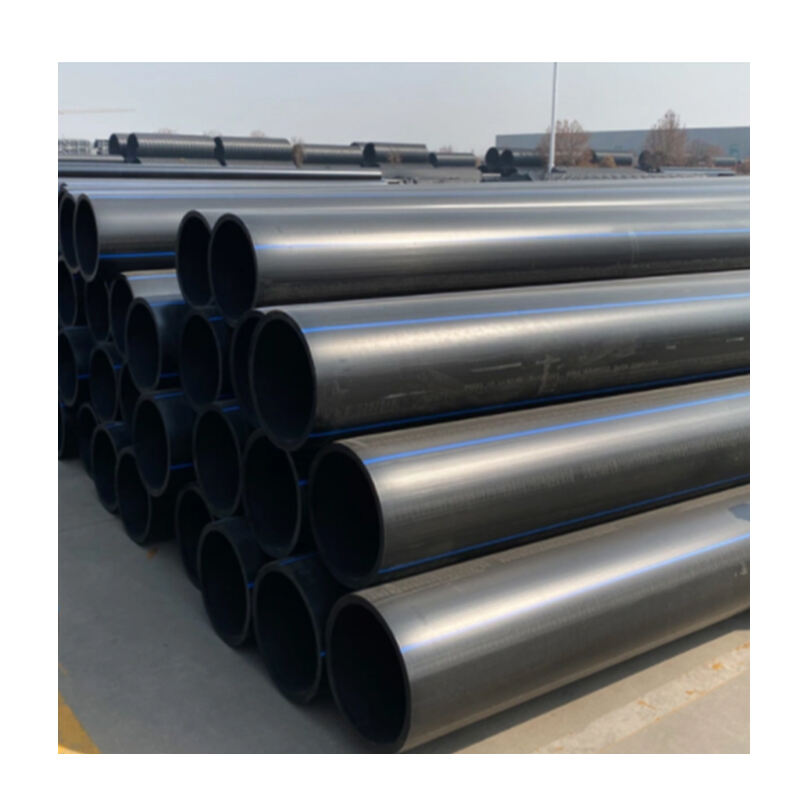

hdpe խողովակ: Հիմնական նյութը ժամանակակից խողովակաշարերի համակարգերի համար

Ներկայացում

ժամանակակից խողովակաշարի համակարգերում hdpe (բարձր խտության պոլիէթիլեն) խողովակները աստիճանաբար դարձել են կարեւոր ընտրություն ավանդական խողովակների փոխարինման համար, իրենց գերազանց կատարողականով եւ լայն կիրառման ոլորտներով: Այս հոդվածում մանրամասնորեն կներկայացվի այս նոր տես

hdpe խողովակների բնութագրերը

hdpe խողովակները, որոնց հիմնական հումքը բարձր խտության պոլիէթիլենն է, ունեն մի շարք եզակի ֆիզիկական եւ քիմիական հատկություններ: առաջին հերթին, այն ցուցադրում է չափազանց բարձր դիմացկունություն եւ կոռոզիոն դիմադրություն, եւ կարող է երկար ժամանակ օգտագործվել տարբեր կո

Դիմումի դաշտեր

hdpe խողովակները լայնորեն օգտագործվում են շատ ոլորտներում: քաղաքային շինարարության մեջ այն լայնորեն օգտագործվում է խողովակաշարային համակարգերում, ինչպիսիք են ջրային մատակարարումը, ջրահոսքը եւ գազի փոխադրումը: դրա կոռոզիոն դիմադրությունը եւ եղանակային դիմադր

արդյունաբերական ոլորտում, HDPE խողովակը լայնորեն օգտագործվում է նաեւ խողովակաշարային համակարգերում քիմիական, նավթային, հանքարդյունաբերական եւ այլ արդյունաբերություններում: դրա քիմիական կայունությունը եւ ճնշման դիմադրությունը թույլ են տալիս HDPE խողովակաշարին դիմակայել տարբեր քիմ

HDPE խողովակի առավելությունները

համեմատած ավանդական խողովակների հետ, hdpe խողովակը ունի շատ առավելություններ: առաջին հերթին, այն ունի լավ բնապահպանական կատարում, արտադրության ընթացքում չի արտադրում թունավոր եւ վնասակար նյութեր, եւ կարող է վերամշակվել եւ վերամիավորվել, ինչը համապատասխանում է կայուն զարգացման պահանջներին: երկրորդը, h

շինարարական տեխնոլոգիաներ

hdpe խողովակի շինարարական տեխնոլոգիան նույնպես անընդհատ զարգանում եւ բարելավվում է: շինարարական գործընթացում, տաք հալածման միացումը եւ ռետինե օղակի խողովակաշարի միացումը հիմնականում օգտագործվում են խողովակաշարի միացման կնքման եւ կայունության ապահովման համար: տ

Արդյունք

ամփոփելով, HDPE խողովակները ավելի ու ավելի կարեւոր դեր են խաղում ժամանակակից խողովակաշարային համակարգերում իրենց գերազանց կատարմամբ եւ լայն կիրառման ոլորտներով: տեխնոլոգիայի շարունակական առաջընթացի եւ կիրառման շարունակական ընդլայնման հետ, HDPE խողովակները, անշուշտ, ավելի կարեւոր դեր են խաղ