أنابيب البولي إيثيلين عالية الكثافة في مشروع استصلاح المياه

في مشروع حديث لإعادة تأهيل المياه، أثبتت استخدام أنابيب البولي إيثيلين عالي الكثافة (HDPE) أنها حل فعال من حيث التكلفة وكفؤ. هدف المشروع إلى تحسين جودة المياه وحفظ موارد المياه من خلال إعادة تدوير واستخدام مياه الصرف.

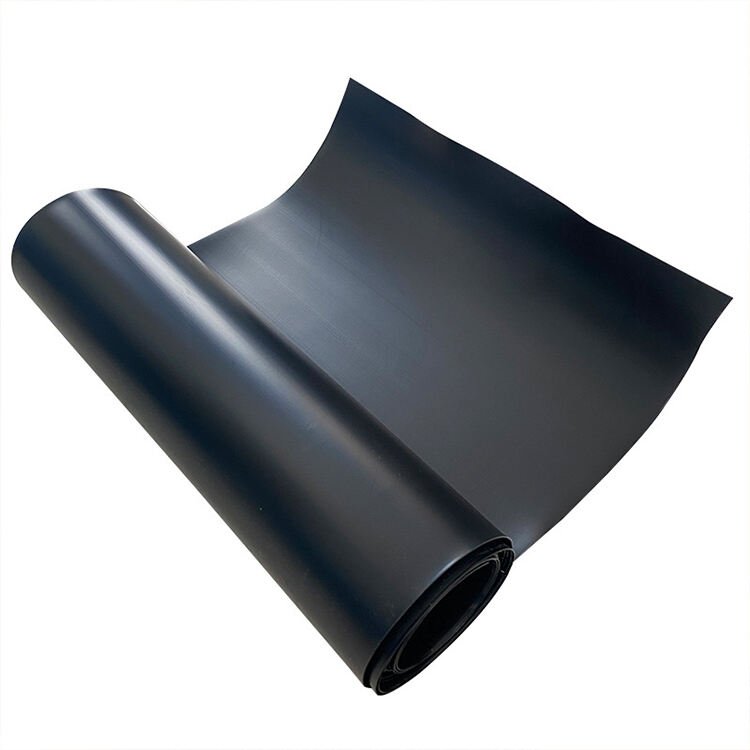

تم اختيار أنابيب HDPE بسبب متانتها ومقاومتها للتآكل والمرونة. كانت هذه الخصائص حاسمة في التعامل مع تدفقات المياه المعقدة والضغوط التي تواجهها مرافق إعادة تأهيل المياه. استطاعت الأنابيب تحمل المواد الكيميائية والشوائب الموجودة في مياه الصرف، مما يضمن نظام نقل آمن وموثوق.

أثناء عملية التركيب، تم دمج أنابيب الـ HDPE معًا بسهولة باستخدام تقنيات لحام متقدمة. وهذا أدى إلى تكوين اتصالات قوية وخالية من التسريبات يمكنها تحمل المتطلبات الصارمة لعملية استرداد المياه. كما أن مرونة الأنابيب سمحت أيضًا بتركيب سهل في المساحات الضيقة وحول العوائق.

بمجرد بدء التشغيل، نقلت أنابيب الـ HDPE مياه الصرف الصحي بكفاءة عبر المراحل المختلفة لمعالجة مرافق استرداد المياه. كانت قادرة على التعامل مع أحجام المياه الكبيرة ونسب التدفق المتغيرة، مما يضمن تشغيلًا سلسًا وكفؤًا. وقد منعت مقاومة التآكل للأنابيب أي ضرر أو تدهور بسبب المواد الكيميائية المستخدمة في عملية المعالجة.

يمكن归ن نجاح هذا المشروع لاسترداد المياه إلى استخدام أنابيب HDPE. لقد جعلت مقاومتهم للتآكل والمرونة والمتانة إياها الخيار المثالي لهذه التطبيق الصعبة. تجاوز أداء الأنابيب التوقعات، مما ضمان نظامًا فعالًا وموثوقًا لاسترداد المياه يفيد المجتمع والبيئة.